The initials PSI stands for Pounds per Square Inch and CFM is an acronym for Cubic Feet per Minute. In the simplest terms for the difference between CFM and PSI charts in air compressors is what they measure. To some extent the names already depict their purpose. That is to say CFM measures the volume while PSI measures the pressure.

Altogether, PSI and CFM are indicators of the maximum air volume and pressure that is normally produced by an air compressor in order to power up air tools. In any air compressor, both pressure and volume are the crucial aspects that determine the performance they will deliver.

Hence, it is important to understand what CFM and PSI charts in air compressors actually are to fully understand their role in delivering a product that will meet your requirements. Just as any other purchase, it is vital to have this knowledge beforehand.

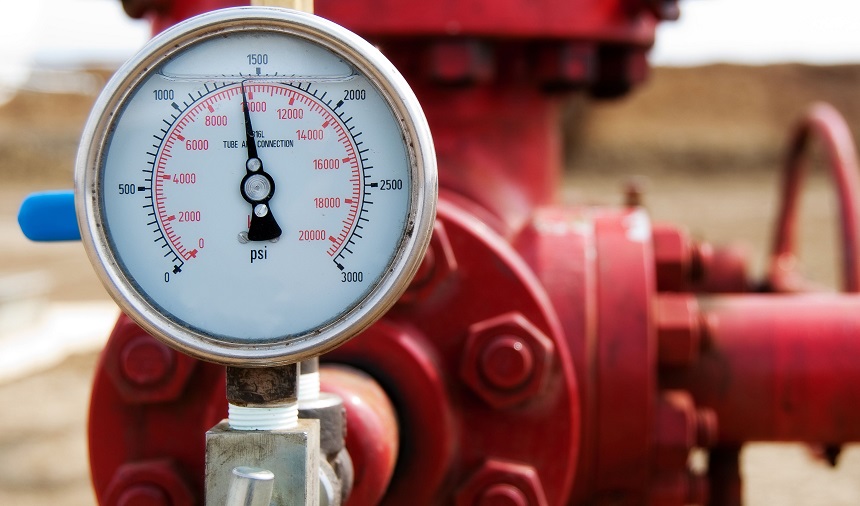

As aforementioned, PSI (Pounds per Square Inch) is simply a metric for calculating that how many pounds of pressure are being exerted on an individual square inch of space. This pressure or force is exerted in a specified area. The role of PSI is to provide power to compressed air.

Furthermore, PSI is used in numerous applications to measure pressure. Some examples of applications are:

It is a common practice to write PSI in lower case letters, when it comes to air compressor specs.

To understand how PSI works Trusted Source Pounds per square inch - Energy Education Pounds per square inch or PSI is an imperial unit of pressure. Using the imperial units of pounds and square inches, it is a measure of force per unit area. energyeducation.ca in an air compressor, here is an example. Consider an air compressor that has output rated for 100 psi*. Now this implies that 100 pounds of pressure is applied per square inch.

Similar to PSI, CFM is a metric for measurement. To clarify, CFM is short for Cubic Feet per Minute and it is so far the most common method of measuring airflow. As you already know, areas are measured in square units. For instance, square feet while volumes are measured in cubic units.

To sum it all up, CFM is used to determine how much cubic feet can be moved or exchanged every minute. When it comes down to measuring, consider a room that is 1,000 ft3. Now with respect to the volume, it will require a 1,000 CFM system to replace all the air each minute.

This also answers the questions for people who are seeking air compressors but do not know how to go on about it. The short answer is that, the best air compressors are the ones that have their function specific to the area you need to use them in. Therefore, if it is a 2,000 ft3 room, you’ll need a 2,000 CFM system.

Certainly, mathematics can be complex. Therefore, calculating air compressor CFM Trusted Source How to Determine Needed Air Pressure for Applications It’s important to know the air pressure requirements of a given tool or application. Learn how to determine the amount of pressure for a given situation. www.quincycompressor.com is no different. However, it is not impossible to learn. There are easier ways to go on about calculating CFM at different pressures.

Now, the objective here is to make a simple equation that will help in getting some idea of how much compressed air will the air compressor provide at varying pressures. The foundation of this equation relies on Ideal Gas Law. In other words:

PV = nRT

It might be familiar to you, something that you learned in school or online. In this equation;

An important thing to remember here is that, air is a mixture of gases and vapor. Therefore, deviation from this law is inevitable based on humidity and several molecular properties of the gases present. Moreover, this law is not adequate for flowing gases.

But here, we will just assume that there is constant temperature. Now moving on to the numbers, consider you have a compressor rated to output 20 CFM at 35 PSI. So,

P = K* (1/V)

35 psi = K*(1/20 cubic feet)

K = 700

Now,

V = K* (1/P)

V = 700 * (1/35psi)

V = 20 cubic feet

In this numerical, “V” is the volume (cubic feet). However, the Ideal Gas Law is only to provide a general idea. The results may not be accurate but if you want to reach more accuracy, and dive into the deeper mathematics of it all, then Bernoulli’s equation is the road to take.

By now you might have a clear understanding of both CFM and PSI Trusted Source CFM vs. PSI Air Pressure: What You Need To Know - Atlas Copco USA CFM vs. PSI Air Pressure: Compressed air pressure and flow seem simple enough, right? You turn the compressor on and compressed air comes out. Well, not exactly. Quite a bit of science like thermodynamics, goes into that air compressor. www.atlascopco.com . The next step in this journey is to understand how they both work together. Before diving into that, take a moment and recall Boyle’s Law.

In the mid-17th century, Robert Boyle derived an equation that connects CFM and PSI. To simplify, a relation between pressure and volume in gases:

P1 x V1 = P2 x V2

In the above equation, P1 is the initial pressure, V1 is the initial volume. Whereas, P2 and V2 are the final pressure and volume. Now, an even simpler interpretation of the equation would be that, volume of a constant mass of ideal gas at a constant temperature is inversely proportional to applied pressure.

For instance, let’s say you are looking a suitable compressor to meet your need. Your requirement will also differ based on what you need. But in this case, let’s say you want something you can move around easily. There’s a range of best portable air compressors in the market. However, you need to be fully aware of the horsepower to generate the required volume.

All you have to do is insert the numbers that represent your portable air compressor’s CFM and PSI. Moreover, you also need to add the desired CFM specific to your application, and the equation will let you know how much horsepower you need for the volume difference.

Let’s expand further on the connection through an air compressor cfm vs psi charts.

The graph, even though general, provides insight on CFM and PSI relation. Based on the PSI you can just find the range of CFM.

It is not rare to confuse between CFM and PSI. In addition to the terrible confusion, air compressor ratings come in various terms. When scouting for an air compressor, you might come across the term SCFM as well. CFM and SCFM Trusted Source UNDER PRESSURE — PSI, CFM & AIR FITTINGS EXPLAINED - Rolair A quick primer about CFM, PSI and air fittings, courtesy of the folks over at Nail Gun Depot. www.rolair.com are interchangeable.

The “S” only stands for standard and rest is the same. Moreover, “displaced air” is the quantity of air the compressor sucks while the uncompressed air coming out is called “delivered air”.

However, higher end compressor lines will mostly make these terms clear for the consumer’s sake. Now for the PSI and CFM bit, both are metrics for measurements and it is common to confuse one for another.

You might come across numbers such as 2 CFM @ 40 psi. Now this only implies that the air compressor will suck in 2 cubic feet of ambient air and compress it. This does not mean that it will suck 5 cubic feet of 80 psi air.

What Is the Right PSI for My Needs?

Finally, coming to the most crucial point of this journey, what is the right PSI for your needs? Before considering the best air compressors, it is important to identify which location of your house or workplace do you need the compressor for.

Moreover, do you require a portable air compressor or do you need one for your garage? Since we have already gone through air compressors and portables, let’s talk about something suitable for your garage.

Now, this is important, since the only way to determine the right PSI for your needs is to first understand what sort of air tools will you be using and what are their requirements. Only then, will you be able to choose the best garage air compressors.

You are already familiar with what PSI is, and its relation to CFM in air compressors. That being said, most air tools are designed to operate in the range of 70 – 90 psi. However, you should be able to find the specific requirements for your tools in the manuals.

For home use, you can find air compressors that will offer up to 150 PSI, and that is more than enough to power all the air tools you’ll be using in your garage.

On the contrary, if you require more power than 150 PSI, you’ll need to find a more adequate air compressor, such as the DEWALT D55146 or VIAIR 400P.

Regardless, you must always respect your tool’s PSI ratings that come along with the manual. Some air tools have precise PSI ratings that they are designed to operate at. Providing less or more will not be a “that should do” but it will hurt their functionality. Therefore, it is recommended that you always use your air tools in accordance with their given PSI requirements.

With that, the right PSI for your needs is the required PSI by your air tools.

CFM and PSI charts in air compressors are often confused. Both these measurements are quite important when choosing a proper air compressor for your needs. Fortunately, these values are not that difficult to understand once you have proper definitions of them and some knowledge in physics. In this article, we tried to give you some clear and basic explanations as well as some advanced facts on this matter. Hopefully, you’ve got an understanding of these two indicators and have enough information to make a right choice when buying an air compressor.