If you’ve been following the power tool industry recently, you’ve probably noticed the new technology gaining popularity. Nowadays, brushless motors are making rounds in the market, and most manufacturers have embraced this technology to make various powered tools, including the power drill.

Despite their being one of the fastest growing segments, brushless motors still face stiff competition from their brushed counterparts. In this post, we have compiled a comprehensive overview that focuses on the brushed and brushless drills, together with advantages and disadvantages, to help you make an informed choice.

Brushed and brushless power drills serve the same purpose. Both tools can help you create holes in various materials. You can also use them to drive screws.

The main factor that distinguishes a brushed and brushless drill is the type of motor they use. Brushed power drills use brushed motors, whereas brushless power drills use brushless motors.

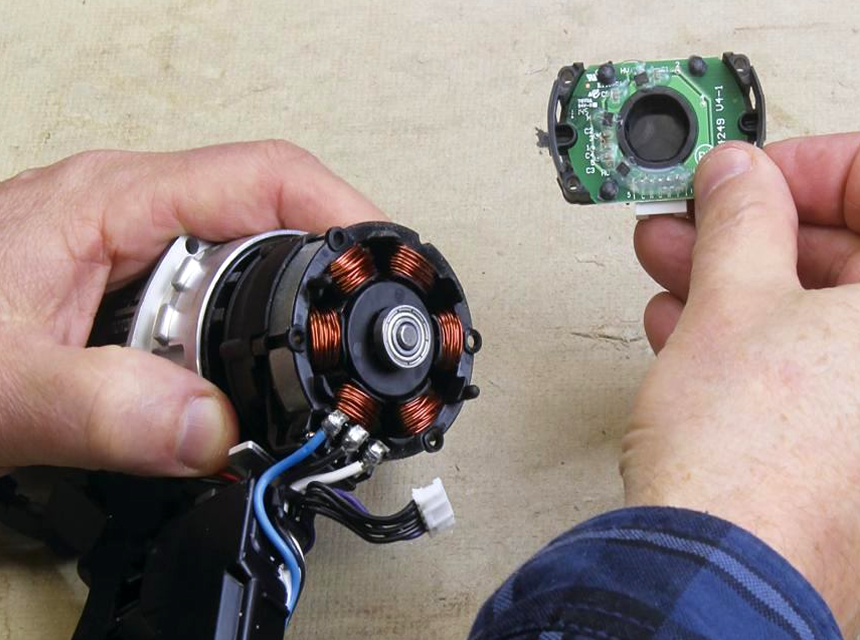

Brushless motors feature a rotor that houses the permanent magnet and a stator that generates an electromagnetic field. The motor relies on an electric controller to generate a three-phase adjustable current that drives the motor’s coils sequentially. This produces a rotational magnetic field in the stator, which drives the rotor’s magnets, making it a spin.

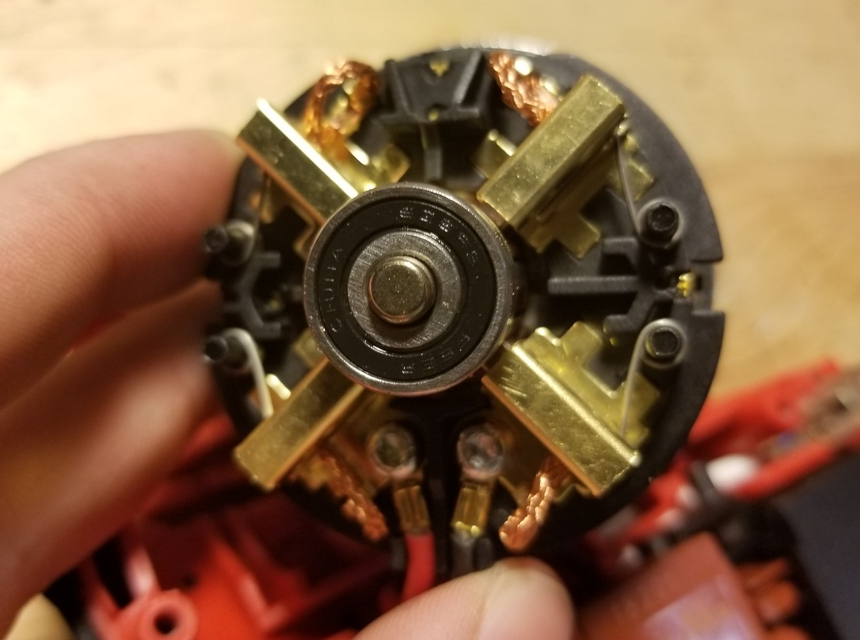

Brushed motors are among the most basic types of DC motors. This motor features a stator that contains permanent magnets and a rotor made up of electromagnets.

A brushed motor works by transferring electric current to the commutator in the rotor through the carbon brushes in direct contact with it, producing an electromagnetic field. You can achieve the spinning motion by repeatedly switching the magnetic pull’s polarity through the commutator.

Brushless motors have several advantages and disadvantages, as discussed below.

Just like brushless motors, brushed motors also offer various advantages and disadvantages.

Here is a detailed comparison between a brushed and brushless drill.

| Feature | Brushless Motor | Brushed Motor |

| Size | Compact and lightweight | Large and heavy |

| Efficiency | 90% | 75-80% |

| Time between failures | High | Low |

| Drive mechanism | Electronic | Commutator |

| Control | Auto-adjustable torque | Manually-adjustable torque |

Previously, brushed drills dominated the cordless Trusted Source Cordless tools: Advantages and disadvantages for your business - New Valley News If you’re thinking of making the switch to cordless then this article is for you. The advantages and disadvantages will be discussed that cordless power tools have on your business. www.newvalleynews.co.uk and corded category in the market. However, the development of brushless drills with improved motors, particularly in the cordless drill sector, has made people abandon Brushed drills for their brushless counterparts. This is because brushless drills seem to offer several perks compared to brushed drills.

The performance of a drill majorly depends on its power. Generally, brushed drills perform poorly due to the low power-to-torque ratio.

There are three main reasons why brushed power drills have a low power-to-torque ratio. When you increase your motor’s speed, brush friction also increases, lowering the usable torque.

With too much friction within the brushed motor, the brushes are likely to wear out. Once the brushes wear out, they can no longer send the correct amounts of power to other parts of your drill. After some time, your drill will stop working properly.

Also, too much friction drains your battery power quickly. With time, its strength will reduce, affecting the overall performance of your drill.

However, brushless drills don’t experience frictional losses resulting in high power-to-torque ratios such as the Greenworks 24V Max from Greenworks.

Brushed drills have a shorter lifespan. As we have discussed above, this tool experiences a lot of friction, creating a lot of heat and making the brushes wear out over time. The heat also affects other components of the motor. Most times, a brushed drill can serve you for only seven years.

The good news is that maintaining a brushed drill is quite easy. All you need to do is clean and lubricate the moving parts regularly. Also, replace the worn-out brushes yourself since it is not a complicated process. You can get these brushes at a store near you or order them online at a reasonable price.

Brushless drills on the other hand can serve you for a long time. On average, this tool can serve you for up to 12 years, depending on how you use it. The manufacturer also plays a major role in determining the longevity of your drill. We recommend buying a good tool from a top manufacturer such as one of these best Makita drills.

Maintaining a brushless drill by yourself is difficult since it is made up of electrical components unless you are an expert. Also, maintaining this tool can be costly.

When comparing the power produced by a brushless and brushed motor, the brushless type carries the day. Brushless drills don’t produce friction since they don’t use brushes. Instead, they have a sensor and circuit board that operate without producing heat. This means that all its power goes to torque, increasing the torque-to-power ratio such as in the TECCPO Power Drill. Therefore, you can easily drill holes on any surface, whether you are working on a hard stone or soft sheer rock.

Additionally, less friction means your tool will not produce large amounts of heat. As you already know, large amounts of heat are not good for your drill. Heat wears out your drill’s mechanics, making it lose power eventually.

If a brushed motor starts producing weird noises or reduces performance, you can easily repair it. Repairing a brushed motor is quite easy. First, open the motor housing and look at the internal components. Check whether there are any physical damages or signs of burning.

If everything appears to be in order, examine the brushes. Generally, these brushes should have a concave part on one end where they will come into contact with the motor armature. If they are worn out, replace them. Screw the motor housing back together and put it back in the drill. Once you are done, test whether it is working efficiently.

On the other hand, the repair options of a brushless motor are quite limited. If your drill starts developing problems like overheating or low power, take it to an electronic repair shop. These experts will first test your drill and identify the exact issue. Afterward, they will repair it if need be. However, repairing a brushless motor can be quite expensive. In such circumstances, it is advisable to get a new drill.

When the brushless motor receives electric current, its stator coils become electromagnetic, producing a consistent field within the air gap. The contact force between the permanent magnet rotor and the electromagnet stator keeps the rotor revolving.

During the process, windings switch between low and high signals, while the matching windings become energized as the South and North poles. The permanent magnet rotor’s South and North poles align with the stator poles, causing the motor to revolve.

Brushed motors, on the other hand, work with the help of the brushes. When the motor receives power, the brushes transmit power to the armature, which in turn starts acting like a magnet. At this point, the poles start repelling the permanent magnet’s pole, which is part of the stator. As poles repel, the armature coil linked to the motor shaft starts revolving quickly.

A brushed motor features a commutator and brushes. As the motor rotates, the switches open and close while considerable current flows through the inductive rotor windings. During this process, arching occurs at the contacts producing electrical noise. To reduce this noise, consider connecting RC snubbers or capacitors Trusted Source Capacitor | FDA The purpose of this ITG is to acquaint the investigator with the capacitor. Only the basics will be discussed since it is beyond the scope of this ITG to go into great detail. www.fda.gov across the brushes. The commutator’s fast switching can also cause electrical noise.

However, brushless motors don’t have a commutator or brushes rubbing against each other in mechanical or electrical contact. As a result, this motor does not produce a lot of noise.

The overall cost of brushless motors is high compared to that of a brushed motor due to the high cost of electrical components. Also, the technology used to make brushless motors is quite advanced, increasing the production cost. Nevertheless, brushless motors are gaining popularity in the market due to their numerous advantages.

Choosing between a brushless and a brushed drill can be difficult. However, there are several factors that you can consider to make the process easier. If you are going to walk around with your drill, it is important to go with the brushless option since they are lighter and are mostly cordless. Since the technology is complex, buy from a reputable manufacturer or get one of these best Dewalt drills. The brushless drill can also be a perfect choice if you want a tool that offers efficiency. Additionally, brushless motors can serve you for a long time without needing a replacement soon. Although the initial purchasing cost is high, you will save money in the long run.

However, if you are on a tight budget but urgently need a drill, settle for the brushed option since it performs the same functions as its brushless counterparts. Also, repairing this drill is quite easy since you can do it yourself. Finally, the brushed drills are suitable for home improvement DIY projects. There is no need to spend too much money on a tool you will use once in a while, and you can get some of the best cordless drills under $100.

Brushless vs. brushed drill is a debate that will never end since both have their set of advantages and disadvantages. Therefore, it is upon you to decide which drill best suits you according to your needs and budget. However, you need to be careful to avoid wasting your money.

To avoid making mistakes, look online for more information about brushless and brushed drills. You can also go to the nearest tool store and ask for directions. If you go through our post, you should be able to make an informed choice at the end.