Air compressors are a must-have for factories and workshops as they have myriad uses. Home DIYers also make the most out of them. Today, you can find an air compressor almost everywhere from your neighbor’s garage to an auto workshop. They come in many different forms that you have to choose one depending on the type of job you need to do. Some of basic uses of an air compressor include; filling gas cylinders for industrial use, creating enough power to run pneumatic tools and pumping up tires and other inflatable objects.

As an engineering manager for a company or an enthusiastic home DIYer, it is important to know how air compressors work. Such knowledge would help you make the right decisions. We have provided a detailed guideline that answers virtually all the questions about an air compressor’s functionality. We have also addressed the different types of air compressors, how they work and their differences.

An air compressor is a tool used by various industries to provide continuous energy in the form of pressurized air. It was invented in the 19th century and since then, it continues to be the most widely used tool in factory and workshop operations. Some industries like metal work can’t do without air compressors.

Most manufacturing companies prefer air compressors because they are affordable and durable. The high-quality models require little maintenance and repairs. They are also more lightweight and compact compared to other centralized power sources.

There are 2 main types of compressors; the scroll compressor and the rotary screw also known as the reciprocating compressor. Each of them has different uses in the commercial and domestic settings. Mostly, they supply air for filling up inflatable objects like tires or they supply power for operating tools like spray guns, drills, staplers and sanders.

How does a compressor get air?

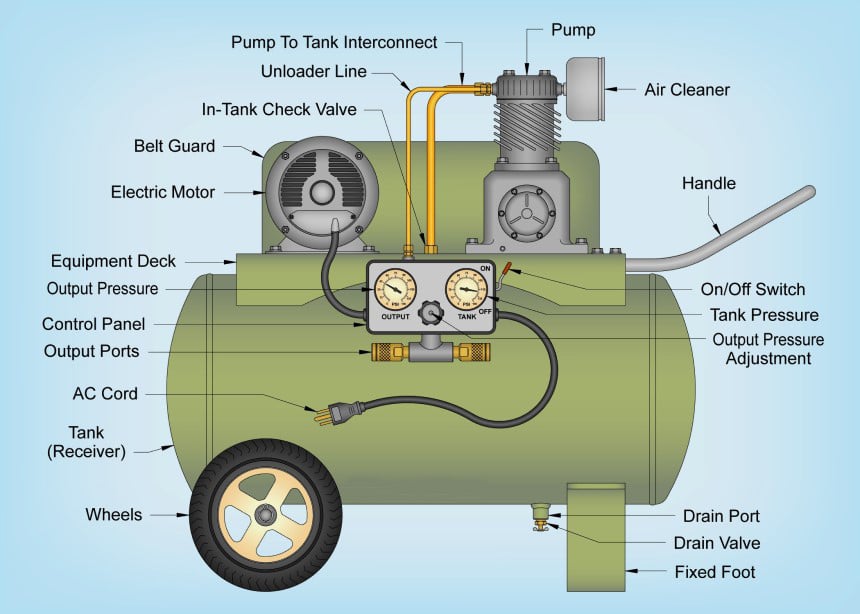

How does a compressor get air?Piston air compressors (many compressors employ the reciprocating piston technology) get air by raising the pressure and reducing the volume of the air. Some of the critical parts of an air compressor are: a storage tank, a gas or electric motor, a pump for compressing the air, and inlet and discharge valves that draw in and release air respectively.

To get air, a compressor draws in some through the inlet valve then create a vacuum to reduce its volume. The vacuum then pushes the air out of the chamber into the compressor’s storage tank. When air pressure builds up to a maximum limit in the storage tank, the compressor goes off. It turns back on when the pressure drops to a certain level. The entire process is referred to as the duty cycle.

Every single compressor compresses air using air displacement. The internal mechanisms of the compressor move to push air through the chamber. The two main types of air displacement used to compress air include:

This is the most common method. It involves air being drawn into a chamber then the compressor reducing the volume of the chamber to compress the air. The air is then moved to a storage tank for later use.

Also commonly referred to as non-positive displacement, the dynamic displacement uses an impeller with rotating blades to draw air into the chamber. The motion of the rotating blades creates energy that builds up pressure in a short while. Dynamic displacement creates large volumes of air and works quickly, thus can be used with turbo compressors.

Since positive displacement is the most common air displacement method, there’s a whole bunch of positive displacement air compressors. Each of them works differently. Some are best suited for industrial use while some can only be used for domestic purposes. They include:

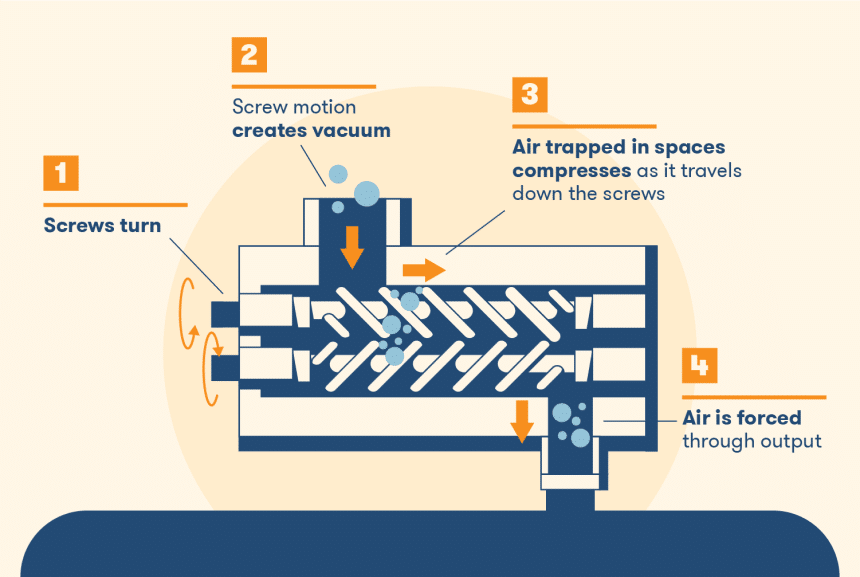

Why should you get a rotary screw compressor? It has excellent power capacity, a low initial capital cost and it is extremely easy to maintain.

You might not like them because as much as they are easy to maintain, they require frequent maintenance checks. They also have very limited cooling abilities.

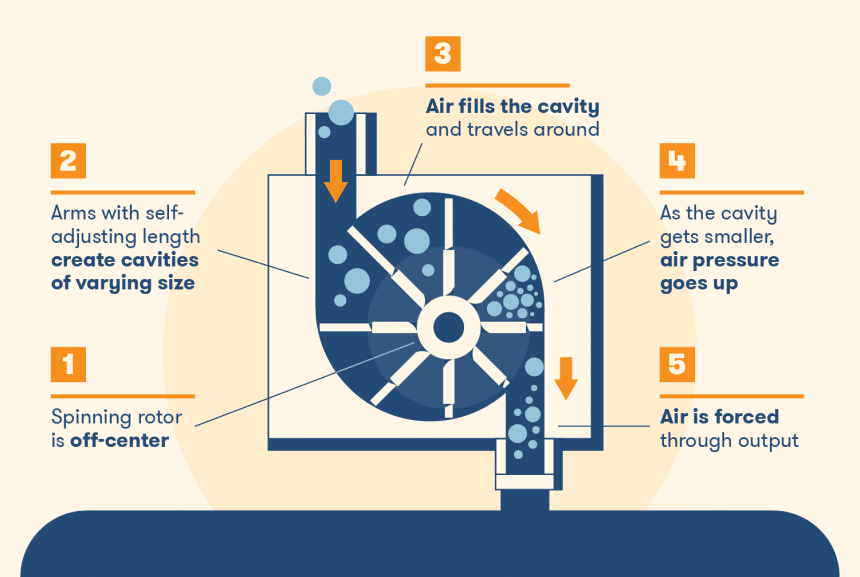

This another popular air compressor. It is also known as the piston air compressor. It has a rotor that spins and makes a piston move up and down. When the piston goes down the air is pulled into the chamber and when it rises up, the air is compressed and forced back outward. This is the same principle that the combustion engine of a car employs.

Some of the main features of a reciprocating air compressor include a crank shaft, a cylinder, a connecting rod, a piston and a valve head. Single stage air compressors use a single piston while two-stage compressors use 2 pistons and can pressurize more air. Piston compressors are much noisier compared to other designs because of how their parts move and generate friction. Though the dual and multi-piston models are much quieter because they get to split up the workload.

The main reasons why you should get a reciprocating air compressor are; it is more energy efficient and it cools down quickly. Its only downsides are; it has more complex parts, thus hard to maintain and its initial capital cost is much higher.

The single-stage and dual-stage piston compressors are the most common types of air compressors. They both share the same functioning principle, except the dual stage air compressors have an extra step in the compression process. The Single-stage air compressors feature a single chamber and air is compressed once, while a dual-stage air compressor has 2 chambers and the air is put through compression twice.

Most people tend to differentiate the 2 compressors using the number of cylinders each of them has. They both use 2 cylinders, only, single-stage compressors have same size cylinders while dual-stage compressors have cylinders of different sizes.

A single-stage compressor draws air into a cylinder then it compresses it once when the piston moves within its vacuum system. After compression, the air is sent to a storage tank for later use. The compression’s power is usually measured in Pounds per Square inch (PSI) or Bar. The PSI will be high if the compressor has more power. Most single-stage air compressors compress air at a standard rate of about 120PSI.

Dual-stage compressors, on the other hand, have two chambers. They compress the air in the first chamber using the same principle as the single-stage air compressors then send it to the second chamber and compress it again. In second chamber, air is compressed at a rate of about 175 PSI.

Both single-stage and dual-stage compressors are powered by either a petrol or electric motor. It is the motor that drives the piston and makes compression possible.

Since they function similarly, single-stage and dual-stage air compressors can be used for the same tasks like operating high-powered tools in a manufacturing plant or basic tools like a drill.

The single-stage air compressors are mostly used for domestic purposes like doing small workshop jobs that need handheld tools, and Home DIYs.

Dual-stage air compressors are best suited for large-scale work like vehicle repair. They are mostly found in pressing factories and manufacturing plants.

Lubrication is another way of comparing air compressors. Some compressors use oil while other don’t and they are both suited to different jobs. The kind that use oil require their pistons to be in top working condition, must thus be lubricated with oil. Some also use oil on the cylinder to facilitate compression.

How do oil air compressors work? They require oil to be added to their piston area regularly, the oil also needs to be changed as often as the manufacturer’s instructions suggest. They are quite weighty and costly but they are robust and ultra-durable. They last longer than oil-free compressors. They also tend to make a lot of noise compared to their oil-free counterparts.

Since they are heavy and durable, oil-based compressors are best suited for heavy-duty jobs in the industrial and commercial settings. Therefore, if you are looking to invest in the best industrial air compressor that is robust and versatile for your business, an oil-based compressor is the way to go.

Some of the common uses of an oil-based air compressor in a commercial setting include:

· Providing power for operating pneumatic construction tools like drills and nail guns

· Painting and repairing vehicles

· Providing power for operating dentistry tools and other tools in the medical setting

· Creating snow banks in ski centers

· Operating air cleaning tools like blowguns

Oil-free compressors

Oil-free compressorsThese compressors, unlike oil-based compressors, feature a lubricated cylinder with a non-stick material like Teflon, thus don’t require any maintenance to work well. They are incredibly light-much lighter than the oil-based compressors because they have a compact build. They require less parts to operate, plus they don’t carry the weight of the oil that oil-based compressors have.

Oil-free compressors also have a pretty basic design and are remarkably affordable. Another praiseworthy feature of these compressors is their quiet operation. If you would not like a noisy working environment, be sure to opt for the best quiet air compressor Trusted Source How Do Air Compressors Work? Guide & Infographic | Direct Air Check out the full guide to finding out how different types of air compressors work. The full guide includes an infographic. www.directair.co.uk . The California Air Tools 6010LFC 1.0 HP Ultra Quiet and Oil-Free Industrial Air Compressor is one of the most popular air compressors preferred for its quiet operation. It only produces 60 decibels and it promises a minimum of 4000hours before wearing out.

On the flip side, oil-less compressors to heat up faster to very high temperatures. They are also less durable because their non-stick greasy material (often Teflon) loses its lubrication abilities and wears down over-time. Because of this, oil-free compressors are mostly used by those in need of an ultra-lightweight and low-maintenance tool for domestic purposes.

They are a fantastic choice for small-scale jobs like blowing up balloons, all types of DIY and home workshop jobs. They also come in handy in industries that strictly don’t need their products or consumer coming into contact with oil. For instance, the food and beverage industry would be in trouble if they encountered oil contamination. The dental and the pharmaceutical industries also have no choice but to use oil-free compressors.

Air compressor speed

Air compressor speedAir compressor speed is another crucial factor to consider when choosing an air compressor for your business or industry. There are 2 main types of air compressors in terms of speed; fixed and variable. The primary differentiating factor between the two air compressors is how the motor gets its power. Otherwise, the compression element is pretty much uniform with all pair compressors. In fact, how the motor operates not only affects the compressor’s speed but also determines its efficiency, usability and lifespan.

These are also popularly known as VFD (Variable Frequency Drive) or VSD (Variable Speed Drive) compressors. They operate by adjusting the motor speed automatically according to the demand for air. This is made possible by the compressor’s system that converts voltage from the mains power supply into a variable frequency.

The system draws in power then converts it twice. First, it uses diodes to convert AC power to DC power. The AC power is cleaned by a capacitor then transformed into DC power with a transistor. The transistor acts like switches that control the frequency of power sent to the motor, thus controlling the motor’s speed.

VSD air compressors have a technology that allow close control of the motor’s speed and the amount of air compression used. This gives you, more agency over the machine. They are also more power efficient, as you have the ability to control your output or use what you only need. This is why it is highly preferred by many manufacturing companies.

On the flip side, VDS compressors are not the best for applications that require a continuous stream of power. They also require a hefty initial capital cost and frequent repairs and maintenance that can be expensive as well.

These compressors unlike VSD compressors send a consistent stream of power to the motor, offering you a reliable frequency in all of your compression applications. Fixed speed air compressors are vital tools in any industry that has continuous power demand.

The upsides of a fixed speed air compressor is that its initial capital cost is much lower and reasonable compared to a VDS compressor. It is also much easier and cheaper to maintain.

Its only downside is that it is less efficient at saving energy, thus expensive to run.

Power in an air compressor is often thought of as horsepower, measured in HP.

There are loads of other ways of determining the amount of power in an air compressor. Cubic Feet per Minute (CFM) is one of them. CFM allows us to know the rate and volume at which a compressor compresses the air.

A compressor with a high CFM rate is likely to produce more air and is often used for large-scale applications like industrial work.

The rate at which outside air enters a compressor’s cylinder is often influenced by environmental factors like wind, humidity and heat. Manufacturers use Standard Cubic Feet per Minute to consider both internal factors and these external factors. The SCFM combines CFM and the external factors.

Another common Air compressor power rating is the displacement CFM. It shows the efficiency of the compressor pump by pulling information from the RPM (Revolutions per Minute) of the motor. It also gets information about the volume of air that the compressor’s cylinder can displace.

CFM can also be measured in terms of delivered air. The amount of air discharged is measured and the number is referred to as CFM FAD (Free Air Deliver. It is important because it is used to measure the air delivery of certain tools.

Air compressors have increasingly become an invaluable tool in our every day lives. We use them for various applications like filling up our tires and balloons, in the air conditioners, and in construction tools like spray guns and drills. Buying the best air compressor is one thing but wrapping your head around its functionality is another thing.

Whether you are an enthusiastic home DIYer or an engineering manager at a busy motor parts manufacturing firm, you should know how air compressors work. The information we have provided in this guide covers various types of air compressors from oil and oil-less air compressors to tow behind air compressors. Being able to tell the difference between different types of compressors, their functionality and applications will help you make the right decisions when choosing a compressor for your needs.