Drilling through metal is not your everyday task, at least for most people. The majority of the time, drilling projects are thought to be for wood. However, you can drill through metal and there are even special tools or drill bits that can be used to get the work done.

While our minds often think of wood for drilling, there are people through drill through metal regularly as well. When learning how to drill through metal, there are a few things that you should know. Properly setting your equipment and making sure you have the right equipment will make a difference.

You might also consider what type of metal you are drilling through, what you plan to use to drill this hole, and how you want it to look when you finish. Check out our guide to learn how to drill a hole through metal the right way.

Drilling the hole is really the easy part of this process. Understanding how to do it safely and efficiently is the more challenging topic to consider. When you start drilling, it will likely only take a few seconds to finish drilling a single hole. But first, you need to set up to do so properly.

Grab one of the best cordless drills and let’s get started!

The first thing that you need to do is find the center Trusted Source X Marks the Spot: Finding the Center of Mass - Scientific American Scientific American is the essential guide to the most awe-inspiring advances in science and technology, explaining how they change our understanding of the world and shape our lives. www.scientificamerican.com of your object. The center won’t always necessarily be the same or even the real center of the object. This will likely depend on what you are needing to drill a hole for.

For example, if you’re drilling a hole for hanging purposes, this is going to be more for center mass to ensure that you can balance the item with the hole being drilled.

One more snippet on the center. This is the center of the hole you need to drill. It gives you a placement for the drill bit so that you can ensure you drill where you really need to on this piece of metal. Some people will use a center punch tool in order to help create a noted space for the center.

In most circumstances, you might benefit from a pilot hole in your metal. Pilot holes are typically used when you need to make a large hole in the metal. How it works is you use a small bit to drill the first hole and then you follow up using the larger bit for the full hole that you are needing.

This provides a guideline for the larger bit and will make it a little bit easier for the drill to do its work. If you’re needing a good drill to work with, you might try one of these best Makita drills that are known for their ability to handle tough tasks. Just be sure you also have a quality drill bit too!

Line up the smaller bit with the centering that you just created and drill through using the small bit. Then, you can switch to your larger bit and create the full hole that you need. It’s up to you when to determine at what size to use a pilot hole. Most experts recommend using pilot holes for any drilling size over 1/2 an inch.

One thing to be aware of is that there are several different types of metal. Some metals are more flexible while some metals are very hard. You also have thin metal or thick metal and that can make a huge difference in your drilling practices too.

Being familiar with the type of metal that you are working with will be an important element in learning how to drill through metal. It’s not just about how to drill through metal with a hand drill to drill a hole through metal but rather how to work with the type of metal and the type of hole that you really need.

Before you get started, there are a few things you might need to prepare. We recommend a pair of safety goggles like this option from DeWalt. When you drill metal, it’s easy for little shards to spray out or even end up on your fingertips. Getting metal in your eyes could cause major problems.

We also recommend investing in some drilling oil like this option from Evo Dyne. Drilling oil can help the drill bit move more smoothly through the metal, preventing sparks and rubbing as you drill.

Take a look at some of these common types of metal, with instructions for drilling holes through them.

Drilling through metal studs can be a challenge because you have to find the stud but you also may not know exactly how thick it is. Chances are you have to drill through other materials and that metal stud as well, depending on your project.

Unless your metal stud has not been placed yet, you’re going to need a good hand drill to make this happen. Don’t worry, the classic dad joke of using a stud finder for finding themselves still works with a metal stud too.

Here are some steps for how to drill through metal studs:

Drilling through thick metal can be complicated. You have to be able to drill slowly and steadily and you need a strong drill bit that can handle the slow speed and the thick metal. Whether you use one of the best DeWalt drills or some other quality drill, it’s the bit and the speed that will really make a difference.

When you are drilling, it’s a common misconception that if you drill at a faster speed, the process will work much better. While there are times drilling quickly is effective, that is not always the case. How to drill through thick metal is to work slowly and you will likely also need a pilot hole as well.

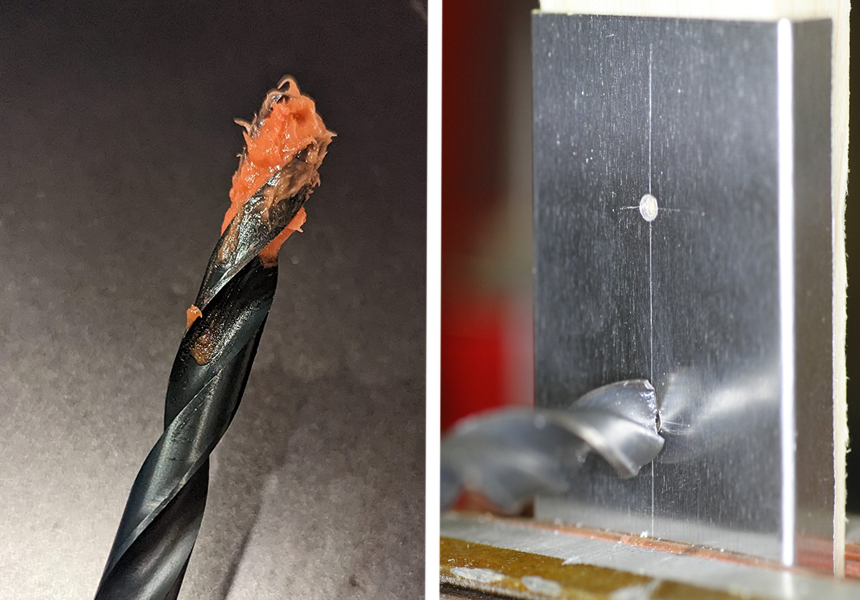

For thick metal, be prepared to use cutting oil. The friction that is created during the drilling process can grind, chew, and make the bit and metal extremely hot. When you use cutting oil, it helps to lubricate during the drilling so you don’t run into problems.

Set your drill to a low speed and work your way through. If you are cutting multiple holes, allow the drill to cool in between.

Thin metal is easier to drill through because the drill bit doesn’t have to work nearly as hard to get the job done. However, you do have to be careful not to bend or warp the metal while you are drilling. For instructions on how to drill through thin metal, you need to be able to clamp the metal to secure it down.

You also need a drill bit that is going to be gentle but still able to easily pierce the metal when you get started. Be sure you’re using a drill bit rated for metal but also one that isn’t going to be extremely rough or aggressive as you are drilling.

You should still lubricate your drill bit with cutting oil as metal does cause friction against the bit and can wear it down quickly. Other than that, just drill slowly after finding and marking your center point location on the metal.

Hard metal can be a challenge, much like thick metal. The reason is that it takes a lot more time and power to be able to drill through it. You need to be sure you have a drill bit made of titanium, cobalt, black oxide, or even high-speed steel.

While you can use any of these for most metals, we recommend using a black oxide or cobalt drill bit when working with hard metals. These materials are much stronger so they will be able to better penetrate this hard surface without breaking or bending.

Learning how to drill through hard metal is easy but you will need to remind yourself to be patient and take it slow. Remember that moving too fast is more likely to damage your drill bit and less likely to drill as you need it to.

On your drill, switch to a slower speed but use a high-quality drill bit. Start by using a center punch to make your mark. Since this is a hard metal, use a pilot hole to take some of the stress off your drill. Follow up with the final hole using your preferred drill bit.

How to drill through sheet metal is a similar concept to drilling through these other types of metal. What you need to realize about this material is that it’s typically thin but it can also be hard metal. So, you need to combine the knowledge of how to drill through metal from each of these categories in order to do it successfully.

Just like with the other metal materials we’ve described here; you need to be able to stabilize the material. Many people will place a board or piece of wood beneath the metal for this stability. You can also clamp it. This helps to combat the thin nature of the metal.

Remember to use some cutting oil and the proper type of drill bit before you start. Move slowly as you drill the necessary hole. Moving slowly should help you to make it through without overheating or wearing out your bit.

Learning how to drill through metal requires a little bit of skill, a little bit of knowledge, and a lot of patience. You can use either a drill or a drill press. The trick is to make sure you have something that will operate with plenty of power and at lower speeds.

You need the power to combat the material of metal and you need to move slowly to avoid making the metal a bit too hot. The friction caused by drilling can quickly wreak havoc on either piece if you don’t do things carefully.

Lucky for you, the experts have shared a ton of tips to help learn the solutions to achieve the best results. It may take some practice but once you understand the tips, you will be drilling metal like a pro in no time.

Here are your top tips:

Protection is a must. When you are drilling through metal, this will most definitely produce metal shavings. If those metal shavings find their way into your eye, it could cause a corneal abrasion or a scratch on your eye.

Those shavings in your eye can be impossible to find and you shouldn’t try to dig them out on your own. If they aren’t treated, they can cause further damage to your eye. The best way to prevent them is to use safety goggles while you are drilling.

We also recommend using work gloves. This can help prevent shavings from getting on your fingers where you accidentally spread them elsewhere later. It’s simply not worth the risk.

A sacrificial board is a board that you can use to support the metal and won’t care if you drill a bunch of holes in it. Just grab a piece of scrap wood to place under the metal piece you’re working on. This is all about stability and it will ultimately help the drilling to go smoother without twisting and tearing.

A lot of people will place this sacrificial board on each side of the metal because it makes drilling through the metal slightly easier. This is particularly true if you are learning how to drill through thin metal or how to drill through sheet metal.

The added stability makes the cut smoother and easier to accomplish.

A dimple is basically a starting point for your drilling process. You know what a dimple on someone’s cheeks is. Apply that concept of a small dip in the surface onto your metal piece. Before you start drilling, you make the dimple to prep the material.

It’s not a hole but rather a place to begin for the drill bit. When you use a drill bit that isn’t quite as strong or struggles to get started, the dimple can help. The dimple guides the drill bit, keeping it where it should be while making the start of the drilling process easier on your bit.

The best way to make a dimple is with a center punch. There are other ways to do it but you need to be careful about damaging the metal when you do. This dimple should be small and pointed to help guide the drill as you turn on the power.

When you drill into metal, there is significant friction that occurs. That friction creates heat and can quickly warp your bit, warp your metal, or even cause a crack or a break too. One of the most important things you need to do when you’re drilling holes in metal is to lubricate the drill bits to prepare them and protect them.

When you drill really large holes, you might actually have to lubricate a bit more than once while you’re drilling. When you notice signs of heating, stop and take a break to let the drill bit and metal cool. This can sometimes be a slow-going process.

The best way to lubricate bits is to use cutting oil or drilling oil. These are the most effective. If you’re in a pickle and need something quick, you could try motor oil instead but we don’t recommend using this as your go-to solution.

Clamping your materials can be a valuable way to make the material hold steady so you’re less likely to make mistakes. When drilling holes through metal, it’s easy for the drill bit to try to slide or travel. If you don’t have a good handle on the materials, they can also slide.

Drilling through metal is not quick and easy. It’s slow going, which gives a lot of opportunities for things to move around. Clamp down the metal to hold it steady and help your drilling results be far more accurate and smooth.

We’ve said this before and we will say it again. This is one of the most important elements of how to drill through metal. You absolutely must drill slowly as you go. Your drill can be powerful but this is not a race. If you try to drill fast, you will likely tear up the metal and possibly your drill or bit too.

You need to drill at a low speed and without applying intense pressure behind the drill. That drill bit should be spinning slowly. You’re going to let the drill bit do the work rather than forcing it through.

A step bit is not your everyday bit. These are sloped to look almost like a top. They start wide at the ends and come to a sloping point at the tip. They work great for sheet metals and thin metals specifically but you can use them for any metal.

The step bit works by starting the hole at a small size and then expanding to the maximum size of the bit. Rather than drilling one pilot hole and then following up, this leads with a pilot hole and slowly expands the overall diameter to the full width of the bit.

The drill press Trusted Source Drill Press Safety Guide Learn more about drill press and how to use it properly. www.ehs.harvard.edu is a great tool when it comes to drilling a lot of holes. It’s basically an oversized drill on a stand. The drill press allows you to set up your materials, set the machine settings, and then it does the drilling work for you.

This might help you with accuracy, as long as you get the settings right and push the drill press through at a slow speed. There are several different types of drill presses, including large industrial ones or simple benchtop ones that are more affordable.

Finally, when you’re finished drilling, take the time to clean up the hole. The edges can sometimes be rough so this will help even and smooth it out. The best way to do this is to clean away the shavings and then use a slightly larger drill bit that you twist just slightly by hand in the hole.

Drilling into metal works very similarly to drilling through any other material. You just need to be aware of the little tips and techniques that will allow you to drill without breaking your bits or causing you issues. The tips shared here will help you have the best results. Just remember to take it slow and don’t force the drill through with heavy pressure.

Learning how to drill through metal is far simpler when you understand how each little step comes together for the best results. Slow and steady helps your drilling results be smooth and effective. Don’t forget to wear your protective gear while you’re drilling!