The Air compressor is one of the oldest mechanical systems that have survived until date despite numerous technological advancements that have resulted in electrical systems. The market is saturated with numerous types of air compressors, and choosing a suitable one can be pretty daunting. Each air compressor has unique features and settings for different applications and industrial processes. Some of the crucial features that differ in air compressors include piston configurations, fuel, tank size, and motor type. Air compressors also have two different measures for the compressed air output, including; cubic feet per minute (CFM) and standard cubic feet per minute (SCFM).

SCFM vs. CFM: Which is better for your compressor? This article closely examines the key differences between the two technical units and what it means for your business. Read on to understand the concepts fully.

SCFM is one of the terminologies you are likely to encounter when researching or shopping for the best air compressor. Knowing the SCFM rating of an air compressor is key to getting one that suits your needs.

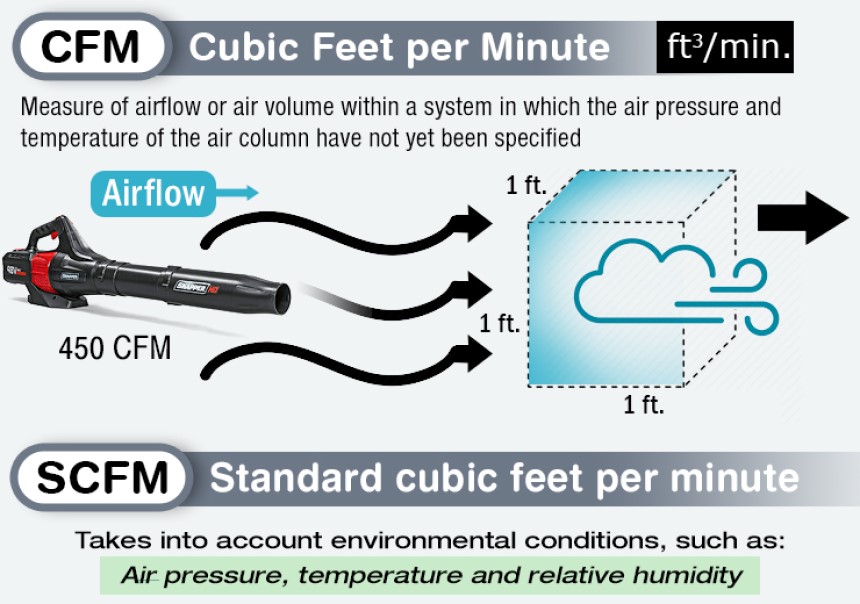

SCFM stands for Standard Cubic Feet per Minute of air that an air compressor can process. The SCFM rating is a vital measurement that can help you figure out the type of tools you can run.

SCFM on an air compressor is the standard measure of its overall power. The word ‘Standard’ in SCFM means the standards for comparing the compressor. You can only compare two units with each other if the air they are pumping is similar. The standard conditions against which the air compressor is compared were agreed upon by the Compressed Air and Gas Institution (CAGI) and the American Society of Mechanical Engineers. The standard conditions are; 14.7 PSI atmospheric pressure, 68 degrees Fahrenheit and 36% relative humidity at sea level.

The standard conditions help you compare one compressor to another. A higher SCFM rating means a bigger and more powerful air compressor because SCFM is a measure of air volume.

CFM means Cubic feet per minute. In the US and many other parts of the world, the air volume is measured in Cubic feet per minute regardless of where it is coming from.

CFM is therefore a technical unit of measure for the volume of air discharged by a compressor over time and its units are based on volume and time. In essence, CFM indicates the volume of air dispersed from a compressor at measured for actual conditions like actual pressure and actual temperature.

There is a bit of confusion brought about by the definition of CFM. Most sources claim that it is the amount of air volume that occurs at an exact pressure or temperature, yet gases are compressible in nature. Since it does not involve any standardization conditions, it is quite hard to use CFM to compare one figure with another. Most times, the CFM rating provided by air compressor manufacturers usually have a margin of error. The best way to find an accurate CFM value of an air compressor is by testing it yourself in a facility. Here is how to go about it;

Step 1: Find the air compressor’s tank volume in gallons. Most products have specification.

Step 2: Divide the tank volume by 7.48

Step 3: Release air from the compressor

Step 4: Refill the air compressor with air and while at it, watch the tank gauge and record the amount of time it takes for the tank to fill up. Ensure you record the PSI the moment the compressor kicks in and out. Label the PSI measurements PSI 1 and PSI 2.

Step 5: Get the pressure in the compressor tank during refill by subtracting PSI 1 from PSI 2, then dividing the value by 14.7.

Step 6: Take the value from step 2 and multiply it with the value from step 5 (pressure of the compressor tank during refill).

Step 7: Convert the value from step 6 into minutes. Divide the value by the number of seconds the compressor took to pump that amount of air.

Step 8: Lastly, multiply the value from step 7 by 60 to get your air compressor’s CFM.

A centrifugal fan is a prime example of a CFM gadget. It illustrates the air volume that occurs at an exact pressure or temperature.

CFM on an air compressor indicates the amount of air it can deliver to an air tool over time. Air tools have different CFM requirements and the CFM rating on your air compressor will determine if you can use certain air tools.

When establishing the amount of compressed air you need in your factory or home workshop, you must first know the CFM to expect from your air compressor’s discharge port. It will help you determine if your air compressor has adequate compressed airflow to power your air tools and other air-consuming applications.

Air compressor manufacturers rate their compressor output differently. Some air compressors may show a discharge rate at an acceptable CFM but if you take a closer look, you will find that the figure is predicated on a much lower pressure than you may need. The discharge rates for a compressor will always be lower at higher pressures than at lower pressures.

Therefore, when choosing the best industrial air compressor like the DEWALT pancake air compressor, or the best quiet air compressor, like the PORTER-CABLE air compressor, ensure that it has both the CFM you need and the pressure that your air tools need to work effectively.

Choosing the correct air compressor for your needs is not only about knowing the different types and controls Trusted Source Air Compressor Types and Controls www.nrcan.gc.ca available. You also need to understand the differences between SCFM vs. CFM. One obvious difference between the two technical measurement units is their full forms. CFM stands for Cubic Feet per Minute while SCFM stands for Standard Cubic Feet per Minute.

Based on the definitions above, SCFM indicates how air pressurized to a standard value will perform when dispersed from the air compressor and delivered to an air tool. On the other hand, CFM is more indicative of the internal capacity of an air compressor.

Another difference is that CFM has no standardization for value calculation while SCFM relies on standard pressure, volume and temperature for value calculation. On this note, CFM provides smaller values while SCFM provides bigger values.

SCFM is the most preferred unit of measurement because it uses standardized temperature, pressure and volume, thus producing more precise results. According to an article by Trident Trusted Source What is the Difference between SCFM and CFM in Air Compressors? - Trident Compressed Air LtdTrident Compressed Air Ltd You may find two different measures for the compressed air output mentioned for air compressors: Standard Cubic Feet per Minute (SCF) or Cubic Feet per Minute (CFM). The experts at Trident Compressor Air explain the key difference between SCFM and CFM and what it means for your business. trident.on.ca , it is better to use SCFM ratings when comparing two compressors because of the fact that SCFM’s measurements are calculated back to set standard conditions.

Here is a summarized comparison table that shows the differences between SCFM and CFM;

| CFM | SCFM |

| Cubic feet per minute

Has smaller numbers Measures higher pressure Has no standardization of conditions Values calculated under 90 psi More relevant to the internal capacity of an air compressor |

Standard Cubic Feet per Minute

Has larger numbers Measures lower pressure Has a standardization of conditions Values calculated under 14.7 psi Indicates how air pressurized at standard conditions will perform at the endpoint application |

The main difference between air compressors and air tools is that the former is rated by the amount of air it can compress in a given minute, while the latter are rated by the amount of air they need to operate. This means that tools can be rated in both PSI and SCFM.

Most manufacturers give their air compressors’ CFM and SCFM ratings measured at sea level. The SCFM rating is an indication of the air compressor’s volumetric flow rate at controlled conditions while CFM is an indication of the air compressor’s flow rate at actual and variable conditions.

When you go shopping for an air compressor, you should consider adding up all the CFM ratings for all the pneumatic tools that the air compressor will power, then compare the figure to what is available from the air compressor.

In a factory setting, the rule of thumb is that the air compressor should be able to provide at least 150% of the CFM needed. This guarantees plenty of reserve power in the system. For home use, you wouldn’t need much reserve power. However, you still need to compare the numbers to know the kind of tools you can use with the air compressor to avoid exceeding its duty cycle.

Let’s say you have an air nailer that operates effectively with 4 to 6 CFM of compressed air flow at a certain pressure. You will need an air compressor that can continuously deliver 4 to 6 CFM.

Wikipedia Trusted Source Volumetric flow rate - Wikipedia en.wikipedia.org defines volume flow rate as the volume of fluid that passes per unit time. Volume flow rate is the amount of air that passes through different components within an air compressor system in cubic feet per minute. Essentially, it is the amount of time it takes for the newly pressurized air to travel from the tank to the last point of its application.

Volume flow rate is a crucial concept in air compressors because it indicates the amount of pressurized air that can pass through an air compressor and the air tools attached to it per second. It lets you know whether or not you can have a certain volume of air to an endpoint application within a second. Some of the factors that affect volume flow rate include; setup, length of pipe, leaks, and number of attachments.

Besides volumetric flow rate, you need to understand what pressure (PSI) means. PSI stands for pounds per square inch. It is the amount of air pressure delivered through an air compressor per inch. Most pneumatic tools require a PSI rating of 40 to 90 psi for successful operation.

A high-pressure rating means the tool has more power for operating. Knowing the amount of pressure and SCFM rating your pneumatic tools need will help you size a suitable air compressor. When trying to establish how much PSI and CFM you need for a project, consider the air compressor’s duty cycle. Most small compressors cannot run continuously and thus cannot deliver compressed airflow at the required volume flow rate and pressure non-stop.

Most air compressor manufacturers rate SCFM at a specific pressure. When an air compressor reads 2.6 SCFM and 90 PSI it means its pump can deliver 2.6 standard cubic feet of air per minute at a pressure of 90 psi.

Some compressors have two SCFM ratings like 2.6 SCFM at 90 psi and 4.2 SCFM at 40 psi. This simply means that the unit’s pump can not only deliver 2.6 SCFM at a pressure of 90 psi but also increase to 4.2 SCFM at a pressure of 40 psi.

The SCFM and PSI ratings refer to the compressor’s pump. The SCFM and pressure you get at the air tank’s outlet are only related in terms of the compressor pump’s ability to replenish used air continuously. For instance, if your air tool uses 9 SCFM at 90 psi from your air compressor with the specifications 2.6 SCFM at 90 PSI, it will work effectively until you drain the air tank and the compressor pump gets a chance to catch up.