The saw Trusted Source Saw - Wikipedia A saw is a tool consisting of a tough blade, wire, or chain with a hard toothed edge. en.wikipedia.org is arguably the most important tool for woodworking. It is a tool or a machine tool for chip-cutting of wood, stone, metal, plastic or other solid materials. Saws work with muscle power, water, steam power, or other sources of energy. But not all saws are created equal – there are different types of saws.

A general distinction is made between hand and machine saws. Manually guided saws such as the foxtail or the coping, Japanese, and hacksaw all work on the same principle. The small saw teeth remove wood shavings as they slide through the wood. The result: a clean cut with manageable effort.

We will explain the various types of hand saws and the types of power saws. We will explain their differences and give you tips on which saw type is suitable for which work. Keep reading!

Hand saws are mostly used in carpentry and woodworking. They are used in cutting wood pieces to various types of shapes while joining or carving wood pieces.

Hand saws oftentimes work with pushing power, that is, the teeth help remove the material while pushing. Japanese saws and most machine saws are pulling. Some types, such as the precision saw or hacksaw, even work in both directions. These saws are particularly common:

The backsaw is also called a trimming saw. It is a small manual saw. It’s a type of hand saw suitable for many materials. The backsaw is a fine-toothed saw consolidated by a metal reinforcement on the back. It can attack many materials of fine or medium thickness and in different forms. The saw has a high cutting precision. The backsaw however is only suitable for sawing thin materials.

The backsaw is a small, easy-to-use saw, especially when used with a tab box and a cutting guide. Note that some back saws may have a so-called “Japanese” toothing which improves the performance and the smoothness of the cut.

A bow saw is a crosscut saw with a metal frame and in a bow shape. Also known as a bucksaw, a Finn saw or a Swede saw, it is used for cross-cutting firewoods and wood branches not more than 150 mm or six inches in diameter.

These types of saws have interchangeable blades since the teeth and jaws are very small.

Scrolling is the technique of cutting the edges (the sides of a panel of wood or other material) to form a curve. Coping saws are necessary for making small curved panels (chair backs, decorative panels, etc.). This explains why coping saws are found in particular in the field of cabinet making.

A scroll saw allows a curvilinear cut, very different from the linear cut but sometimes curved. Also, unlike the sometimes coarse cuts that can be obtained quickly with a jigsaw, the scroll saw allows a very precise action. With its thin sharp blade, a scroll saw allows you to make precise cuts. Motorized versions allow detailed cuts by moving the workpiece yourself by hand.

The fret saw is mainly used for handicrafts with plywood. It has a very thin and fine-toothed saw blade with which you can saw around curves. The fretsaw is a very special saw with which you can do very fine work. Many people remember it from childhood because it was often experimented with in elementary schools.

Due to the saw blade and the structure, it is intended for hobbyists. The blade is round and so you can saw very tight curves. With this saw, you need time and attention to detail.

For the really tough things, like metal, you’ll need the hacksaw. Metals are very solid materials and therefore the hand saw for metal has different features than a wood saw. The teeth are closer together, the saw blade material is different and the workload is significantly higher. Even smaller saw cuts can apply a big force.

For home improvement, there are practical hack saws in which the saw blade is clamped and therefore exchangeable. This is useful because you may want to saw different metals and the teeth wear out frequently due to the material hardness of metals.

The hole saw is also referred to as a hole drill bit. It is ideal for electricians, carpenters, and construction and woodworking professionals. They have annular shapes and their cut generates a circular hole in the material.

They are frequently used for cutting plastics, glass, asbestos, plaster, fiberglass, tiles, granite, ceramics, marble and metals. They are particularly useful for making cuts with large diameter with minimal effort. There is a wide variety of hole saws on the market. You will find some with diamond edges, special diameters, and even double cylinders.

Popular in Japan, where it is known as Nokogiri, it is also now popular around the world. The Japanese saw is comparable to the European hand saw or the fine saw, but only works on pull. The blade is very thin. It has very sharp teeth and ensures you have fine cuts with just some little use of force. There are also models with a double-sided saw blade (Ryōba).

The keyhole saw is a very fine-toothed saw with a very tapered shape, intended for making small, straight or curved cuts in a full panel. The keyhole saw is used to install a switch, to recess a luminaire, or to run a duct or a cable. It allows you to saw plasterboard.

You can use it to cut rounds or make openings in a panel. The saw also allows you to cut wood. The length of the blade is much shorter than on a handsaw. Use it for materials with lesser thickness.

The panel saw is a mechanical saw that can be electric or pneumatic. It’s a big circular saw. The panel saw is intended for sawing panels of wood, chipboard, gross, melamine, laminate, and plywood. The panel saw can be horizontal or vertical. The vertical panel saw is a circular saw that can be moved vertically and horizontally and placed over an inclined table. The panels are placed on an inclined table. The blade is lowered on the wooden panel that you want to saw. The type of blade depends on the choice of the material to be sawed.

Horizontal panel saws are also professional saws. The panels are stacked on the horizontal table, then blocked under the pressure bar. The saw is activated and follows the engine block to meet the panels and saw them. Horizontal panel saws have a sawing device with two blades: the main blade and the scoring blade. The type of blade will depend on the choice of material to be sawed

The pole is essential for pruning works. You can use it for pruning at heights of up to 8 meters. These saws allow you to work safely from the ground. They are sturdy (oval-shaped handle), light (aluminum), and they can accommodate different tools: a ripper, a saw (delivered with its case), and also a catapult for throwing the bags.

A pruning saw comes in handy for gardening. The pruning saw is, as the name suggests, necessary for pruning and sawing branches. Models with a telescopic handle, like the pole saws, which can save you the hassle of climbing a ladder, are also very practical.

But you will hardly be able to cut thick branches with a pruning saw. You will probably need the mechanical help of a chainsaw.

The rip saw is sometimes misnamed universal saw since that name could indicate that it is a saw for all uses, and it is not. But if we asked anyone for a handsaw, this guy would be the first to come to mind. They are the largest of the manual saws that a carpenter or cabinetmaker could usually use. It is mainly used to make general cuts but without much precision.

These large saws, also known as “farmer’s saws” or “forest saws”, which are operated by two men, were mainly used for forest work. Today they are no longer used – except for the maintenance of traditions and customs. The precision saw however ensures a clean, very precise cut and perfect miters.

This is a small-sized manual saw. It is the cabinetmaker’s best friend because, in addition to perfecting wood accessories, the veneer saw is easy to handle. It also guarantees a unique cut quality

The veneer saw blade is serrated and thin. This allows for precise cuts on wood. The teeth in question must be straight. You can sharpen and bend these in case they lean more to one side or the other.

This presentation of the teeth of the blade is one of the specificities of this kind of manual saw. The veneer saw can be called upon in several areas: marquetry, cabinetry, layout, etc.

Wallboard saw, also called drywall saw, a plaster saw, and a collet saw, is ideal for cutting drywall, drywall, plywood, drywall, and other building materials. Drywall saws are most often used to cut holes in interior walls and ceilings for electrical outlets and switches.

It is also ideal for plastering. Its long pointed blade can be drilled in the middle of drywall to start a cut without starting a cut from the edge.

This tool is not stiffened by a bracket but is only made stable by a relatively thick saw blade that measures between 40 and 60 centimeters. Like most hand saws (with the exception of the Japanese saw), the foxtail works in both directions and removes a relatively large amount of material due to the set teeth.

A wire saw is a manual chain saw that is operated by hand. This means that this chainsaw works with muscle strength. The wire saw basically only consists of the chain and handles. At the ends of the chain are usually metal rings, cords, or even wooden handles.

This tool can be used by one person. But handling by one person is much more difficult than by two people. Two people can stand facing each other and push and pull alternately, just like with a conventional saw.

Of course, the hand saw can only be pulled at each end. Two-way sawteeth can be very useful as they can cut both ways.

The wire saw is particularly suitable for sawing fresh green wood and for sawing small trees. The links of multi-link saw chains are toothed on both sides, so the teeth create a cutting notch and are strongly offset. This creates a notch that is much wider than the chain itself. The offset prevents the hand saw from jamming.

One advantage of the wire saw is that it can be used all day, as chainsaws should not be used during midday rest or on Sundays due to the noise level.

Power saws, also called machine saws or electric saws, have evolved a lot over time. Today, you can find a wide variety of power saws depending on the material to be cut and the type of job you want to do. Here, we will see the various types of electric saws.

Power saws are very complete, versatile, and powerful tools. They are used in many jobs such as gardening, construction, carpentry, repairs and are especially popular with DIY enthusiasts. These are very complete equipment that require little knowledge to be able to use them. They are one of the best tools for cutting wood.

Power saws work either with a power connection or a battery. The motors of a lot of chainsaws, however, requires fuel. These power saws are popular:

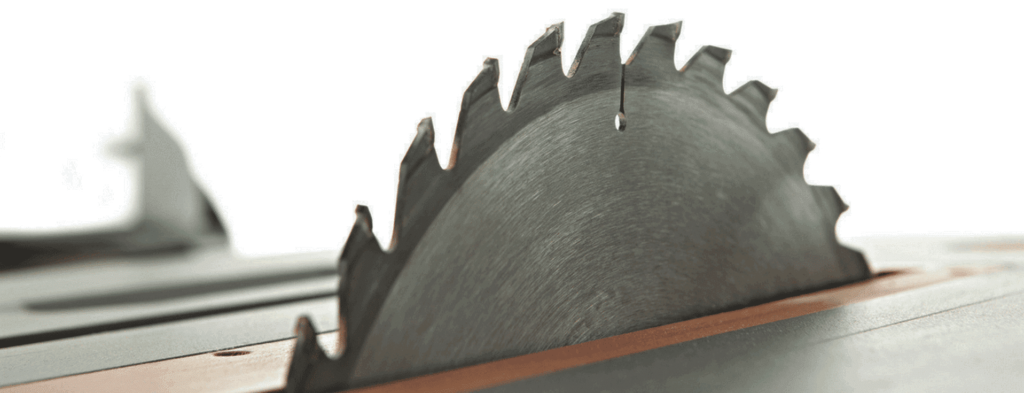

The flexible circular saw is particularly suitable for long, straight cuts. You can also make angle cuts, also known as miter cuts, with a circular saw. However, working with the circular saw should be carried out with particular care, as accidents can occur when you’re not careful enough. For this reason, it is better to avoid using gloves when using a circular saw, as they can easily get caught on the saw blade. There are stationary and handheld circular blade saws such as the worm drive saws.

Jet remains one of the most popular names in the industry. Their 10″ 3HP Deluxe XACTA Saw is one of the best circular saws on the market. The table saw is equipped with a quick-releasing riving knife and has a storage drawer.

The reciprocating blade saw is comparable to the jigsaw but is guided with both hands and usually cuts vertically. When cutting through metal pipes in the house or tree roots in the garden, the reciprocating saw does a great job. The fire brigade also uses this tool during operations.

The versatile and compact tool is very popular with do-it-yourselfers. In contrast to the circular saw, the saw can also saw curves out of a wooden board. It is important to have a sharp blade and to work cleanly. Otherwise, the saw tends to get stuck or the wood will fray. Then some candle wax on the saw blade will help.

A jigsaw will allow you to do a lot of jobs that you couldn’t do with other tools. Unlike a circular saw, the jigsaw will also allow you to make rounded cuts without a hitch. At a weight of around 3 kilos, it is also much lighter and will allow you to be more comfortable when cutting.

Whether you want to make a table, stepladder, lay parquet, install cupboards, or cut a countertop, a jigsaw will help you with a lot of wood-related jobs. Plus, anyone can use it easily, even the less experienced. Note that the tool is used by both individuals and professionals.

The jigsaw is ideal for jobs in a small work area, because to its compactness. Because to its size, you can also easily transport it in a case provided for this purpose, ideal for people who use the tool regularly.

Although compact, the jigsaw can also work with larger saws like the circular saw, especially when cutting pine planks or plywood.

According to most reviews, the BLACK+DECKER BDEJS600C Jig Saw is by far one of the most reliable and time-proven ones. Very powerful, it has a variable speed motor that can generate cutting power of up to 3,000 SPM. It comes with the Bosch T503 3-PieceHardwood/Laminate T-Shank Jig Saw Blade Set.

A saw without a saw blade is like a weapon without a projectile. In the vast majority of cases, a saw blade is therefore preassembled and includes the blades when you buy the saw. But, you may need to replace them when they wear out, rust, lost, or are blunt.

Hence, we will give you an overview of the different types and uses of saw blades – and of course, you can also use them to select your next saw blade.

Used for band saws, they are suitable for lumbering, metalworking, and woodworking. It is highly sought after by DIY enthusiasts because it allows real quality cutting. Often 2 to 3 meters long, this type of blade offers the possibility of providing smoothness and precision on the material to be sawed. However, it is very important to consider the safety aspect in the handling of this blade. Wearing a glove is mandatory because this blade is more volatile than any other model.

The sharp teeth of this saw blade tackle virtually any job in seconds. It can be used for cutting wood fibers. These blades are used for making clean and finished cuts across grains of every wood type. These blades have a lot of teeth.

A dado is a circular saw blade for table saws to cut grooves in wood. They are used for pieces of wood with grooves or interlocking pieces. The dado blades are used to provide slots for the items to be assembled, such as door panels, shelves, or the bottoms and sides of drawers.

Keep in mind that not all table saws are compatible with a Dado blade, so evaluate the specs you have chosen before purchasing one. Conversely, if you know you want the option of using a Dado blade and are in the market for a new table saw, make sure the model you are considering can accommodate that type of blade.

Rip cuts are used for cutting through woods along the brain. This type of blade has a tooth count in the range of 10 teeth to 30 teeth. There are however some exceptions such as the 8-tooth or 6-tooth blades. They are all-purpose blades used for woodworking.

These are circular blades that can have two or more rakers or cutters. This blade was invented by Keene S. Strobel and Peter Heiser. The strobe rakers are fixed at the trailing edges and are meant to reduce friction, effectively ejecting sawdust, preventing distortion and scorching of blade faces, improving the cutting efficiency, while reducing the need for sharpening.

Saws are an indispensable part of everyday work for craftsmen. Hardly any other tool comes in as many different versions as the saw. There are specialized models and saw blades for every workpiece and every field of application.

Saws should not be missing in any workshop. The experienced do-it-yourselfer has a basic range of universal saws for numerous purposes he can choose from.

As we have seen, there are various types of saws. The power saws enable quick, effortless work and have become indispensable in the DIY sector. The hand-held devices impress us with their flexibility and the stationary machines with higher precision and higher performance.

Although many of the saws are still wired, battery technology has also found its way here. This means that in the near future they are likely to displace hand saws.