Welding is a process that has resulted in various achievements for man in the area of construction and manufacturing. The invention of stainless steel Trusted Source Stainless steel - Wikipedia Stainless steel is any one of a group of ferrous alloys that contain a minimum of approximately 11% chromium, a composition that prevents the iron from rusting and also provides heat-resistant properties. en.wikipedia.org , which does not rust and comes with different attributes in terms of strength and workability, has been of impressive help to steel welders and users. However, this development of stainless steel has meant that welders have to adapt their welding methods since welding stainless steel is more difficult than welding other types of materials. In this post, we consider how to weld stainless steel.

When it comes to welding stainless steel, there is no one-size-fits-all process. Why? For one, there is more than one type of stainless steel. Since it was introduced in 1913, stainless steel has undergone evolution and many manufacturers have sought to make specialized stainless steel. Therefore, these enhanced steel have different ways of welding. In this post, we not only consider how to weld stainless steel, but we will also see some of the different types of stainless steel available on the market.

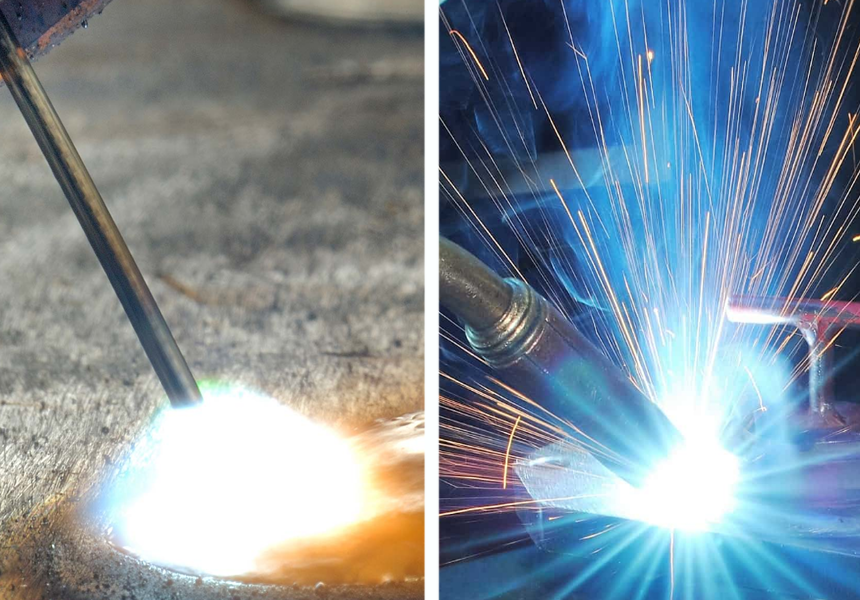

Different factors affect the welding process of your stainless steel. There are different methods used by welders around the world. However, three of these are the most common processes for welding stainless steel. In this article, we will consider each of these methods and consider their applications.

In the meantime, though, let’s consider what tools you will need to weld stainless steel.

Here are the different categories for the things that you will need for welding.

These power tools come in handy in the welding process. Some of the things that you must have in this category include an angle grinder with a paddle switch, and a metal band saw.

Consumables are a common fixture in every set up. Some of these include:

These are arguably the most important pieces of equipment that you need to weld stainless steel. Some models are highly recommended by many of the welders that we have encountered. Reviews indicate that the Everlast PowerMTS welder is one of the best welders on the market. If you are using the MIG process (more about this later), then reviews say that the Hobart MIG welder is a particularly great option to buy.

These are tools that work as the name implies. There are different tools in this category. Some of them include the:

These tools are different from your power tools. Part of what you find included in this category will include:

Welding can be a dangerous process. All of that light, heat, and sparks can be dangerous. Therefore, you must have the correct safety equipment to reduce the chances of injuries. Some of these safety tools are:

For your personal safety, the tools that you will need include:

If you have all of these handy, including, of course, the material to be worked on, then you are halfway to welding stainless steel without plenty of hassle.

There are many questions from beginners when it comes to welding stainless steel. One of these questions is whether it is difficult to weld stainless steel.

Several qualities make welding stainless steel relatively tricky. For example, it is very good at retaining heat. While that might seem a good thing, it isn’t really good if you are a beginner welder. When this material is exposed to high temperatures, it can warp or even distort as you cool it.

Another thing is that stainless steel doesn’t hide any deformities, so to speak. It shows all the scratches that were incurred in the welding process. Steel scratches easily so you must take steps before you begin if you don’t want that.

All of these imply that stainless steel is not the easiest material to handle. It can be tricky for the beginner, although the experienced welder would have a great time working with it.

There are five types of stainless steel. These are categorized based in their microstructure, that is their chemistry and the process involved in creating them. Microstructure is an important factor because it affects the strength ductility and other attributes of the steel.

Although there are five types of stainless steel, three of them are what you’ll find in mast workshops today. These are:

This type of steel is likely the most common option on the market. It has enjoyed widespread adoption and is found in machining and fabrication uses.

Also known as hard stainless steel, this excellent option finds uses in high-grade applications that require hard use. You will find it used in hardfacing and similar applications. ]

The last type on this list is the cheapest type of stainless steel. It is cheaper than the others, which makes it a nice option for people that aren’t looking for expensive raw materials. Because of the lower cost, it is found in consumer products like vehicle exhaust parts.

There is a fourth type, which isn’t as popular as the others. This is duplex stainless steel, and it holds the distinction of being a combination of austenite and ferrite stainless steel. It combines the microstructures of these two types of steel. The advantage is that it feels stronger and harder than the base components. The downside, though, is that it is more difficult to weld.

The last type of stainless steel is precipitation-hardening steel. This steel is composed of other alloys. These new alloys are infused to enhance the strength. While that is great, it makes it more expensive than your regular options. Along with duplex steel, it is particularly suited to high-performance applications.

Before you begin welding your stainless steel, there are certain things that you need to keep in mind. In this section, we will examine some of the steps required for you to get the best from your welding session.

First of all, you must prepare the metal. What this involves includes cleaning the metal or steel before welding. It is important to clean the metal because the material is quite sensitive.

Also, you should get your tools handy. When welding, you should only use hammers and brushes on the steel because it is quite sensitive to carbon steel. What this means is that if you have used a brush on carbon steel, you should avoid using it on stainless steel. If you fail to heed this, there can is carbon steel embedded in the steel, which will accelerate corrosion.

The wire and shielding gas used depends on the type of welding that you are looking to do. It is vital to get the gas choice right.

To improve your starting, it is recommended that you use pure argon or a combination of argon and minor gases.

If you are using the MIG method for welding, then you might employ a high gas flow rate.

Welding stainless steel involves using different techniques, all of which we will consider in this article.

As we have pointed out earlier, there are different ways to weld your stainless steel. In this section, we discuss some of these ways.

Some have wondered if you can MIG weld stainless steel. Well, you certainly can. However, there are things that you must put in place. For one, the MIG machine should be correctly installed before your weld.

For this type of welding, it is recommended that you fit a Teflon wire liner. This offers you good wire feed and will prevent any contamination of the line. Stainless steel is an excellent material with great durability, but it is easily contaminated. Therefore, ensure that you follow the steps here to ensure proper welding of the steel.

Here are some tips on this type of welding:

Out of the several types of welding, TIG welding is considered to be the best in terms of quality and durability. It is therefore the most common type of welding used. In this process, there is low heat input. Therefore, it is an excellent fit for those that want to use a thin material.

The gas used in this process is usually argon, although it is mixed with gases like helium, nitrogen, and hydrogen depending on your project.

This next style is one of the simplest ways of welding. You can either weld it flat or horizontal. While you can do it uphill or vertical, the downside is that the rod quickly burns and you might not get the result that you want.

When stick welding stainless steel, some tips can help. One way to weld correctly is to set the amperage at a low range. With a low amperage, the stick rods do not get so hot quickly and mess things up.

Another thing to do is to pay attention to how red hot the stub is. You should also make the arc fairly tight and use a push angle for vertical welding.

When welding this type of steel, one vital tip to keep in mind is the temperature of the process. You need to keep the temperatures of the weld metal and base metal correct. If not, you will have problems with performance. Here are some tips that can help with temperature during welding.

Use temperature-indicating sticks. These will help to confirm the temperature. The downside is that they come with a limited range.

Well, we have considered the different welding processes for this material. So, which of them is the best? The answer is not as straightforward as you might suppose. You can weld stainless steel with MIG, TIG, and stick welding. Each of these processes gives you varied results.

If you are looking for the best process, here are the factors that you should keep in mind:

If you are looking to create something stylish, then many recommend that you use TIG welding. It offers you a better level of finesse.

However, if you are more concerned about speed and efficiency, then MIG welding might be a better fit for your work.

Some versatile welders can handle different types of welding. You can find the best models here.

Stainless steel is an invention that has changed different industries and created new ones. If you are looking to weld stainless steel, you need to decide the qualities you want it to have. If you want something affordable, spot welding is the best bet. If the material is thin TIG welding would be the right fit. In this post, we have considered the different types of stainless steel and the different techniques of welding stainless steel. We hope that this guide on how to weld stainless steel helps you to get the best from your material.