The serger vs sewing machine comparison doesn’t seem to be ending soon. And with the recent popularization of the former, there’s no better time to come clear about these machines.

You already know that these are two completely different machines. The sewing machine apparently is for sewing. And the serger is for improving the finishes.

The big question, what is the difference between a serger and a sewing machine deserves a clear answer. So, we decided to compare the two types of machines: that is to say a simple sewing machine and a serger machine. It remains important to know when to use a serger or a sewing machine.

Also, as a seamstress and tailor, making use of the serger, in addition to the sewing machine adds a lot of functionality. In the rest of the article, we’ll let you know what each of the machines is, how they work, and when you should choose one or the other.

The serger is a sewing machine that is commonly used at a professional level. Also often referred to as an overlock machine, it is an industrial sewing machine that allow over-edge or class 500 stitches. Normally, they are equipped with what is known as cone holders, tensioners that regulate the threads, needles, the thread take-up, the needle plate, as well as the rest of the elements.

It differs from a traditional sewing machine in that it uses several threads from different bobbins (3-5) with one or two needles. It sews both a straight and a zig-zag stitch at the same time and is especially useful for finishing knits, lycra, synthetics, and all elastics.

Until now, they were used only in the textile industry mainly to treat the edges of fabrics with different finishes, since their seams are extremely versatile, but lately, they are making the leap to domestic consumption.

One of the most popular and functional sergers is the SINGER | Making The Cut S0230. This 4 thread machine has a differential feed and makes up to 1300 stitches per minute.

The server helps one accomplish seam over the edge of one or two pieces of fabric to define the edge or to join them together. The machine cuts the edges of the fabric as it works, making edge finishes quickly and easily.

A serger is mainly characterized by using between one and five threads, which allow the seams to be sewn in a professional way, especially those that are intended for finishing the edges.

In this way, how it mainly differentiates from normal sewing machines is that different sections allow several threads to be used at the same time, in addition to also including blades to cut the fabric.

An overlock sewing machine has a few features that make sewing much easier. It allows you to spread fabrics, make different types of decorative stitches, create ruffles on fabrics, as well as join several pieces of fabric more easily.

A serger is a must-have when you need to see knits, stretchy fabrics, fleece, or sweatshirt fabric. With it, you can make seams and overlock in just a pass. You can make stunning rolled helps both on sheet and light fabrics in a few minutes.

Its operation is simple. It’s only necessary to place the needles and thread them correctly. Then, you will have to adjust the length of both the threads and the stitches. You’ll need to adjust the feed, place the blades in the corresponding place as well as the fabric. Finally, you would only need your foot on the pedal to start sewing.

Yes, they are. An overlocker and serger are just different names for the same type of machine. They both perform overlocking stitches which look a lot like knitting more than sewing.

This handy video explains everything about sergers, whet they are, and how they work.

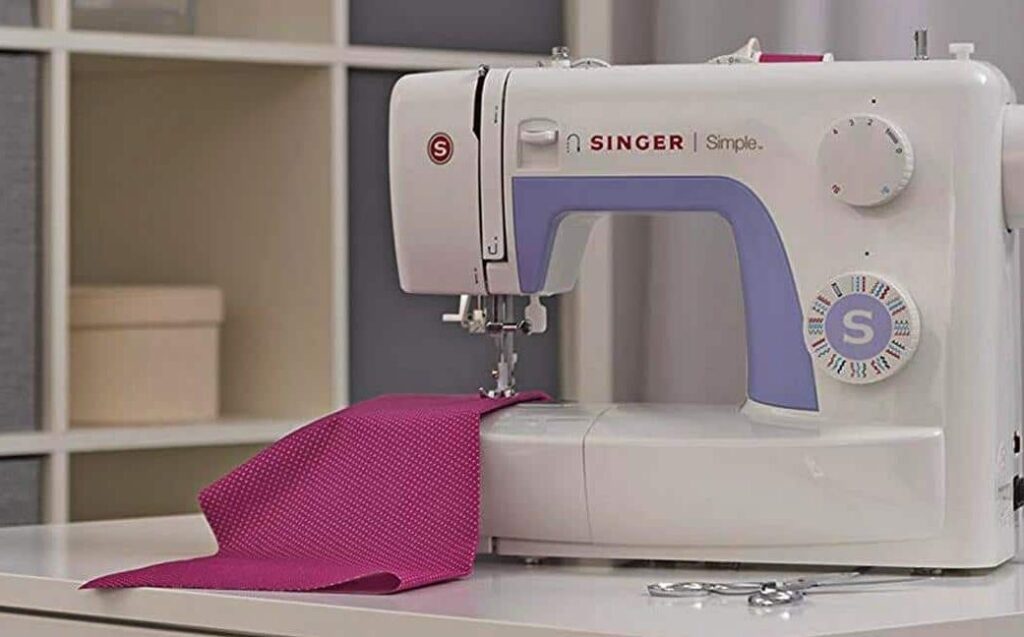

A sewing machine is, as its name suggests, a machine or mechanism that allows you to sew or join textile materials with thread.

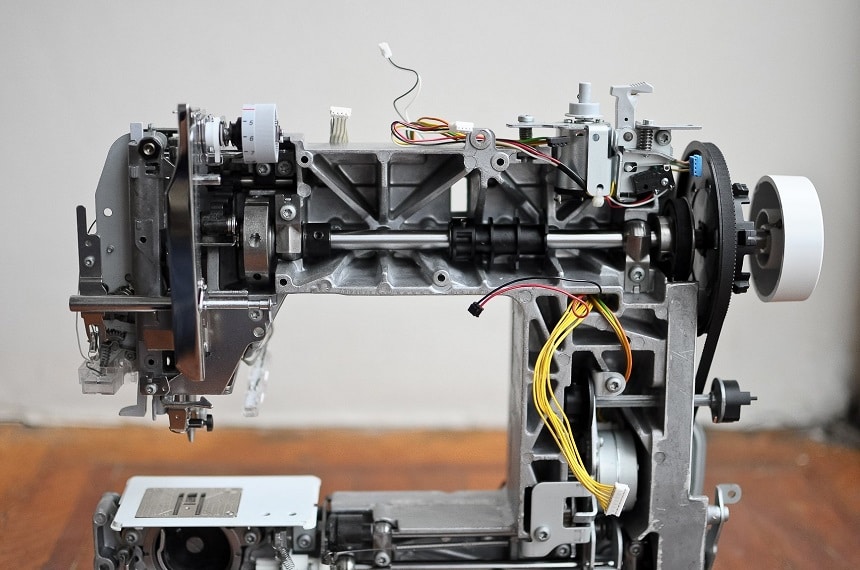

The main components that allow a sewing machine to fulfill its function are the motor, the spinning system, and one or more needles. In this way, they can sew at incredible speeds and with great ease.

Today, there are both mechanical and electronic sewing machines on the market.

They are divided into two large groups, depending on whether their mechanism is started by human force or if they have an electric motor that fulfills that function: the first is mechanical sewing machines and the second, electric sewing machines.

A mechanical sewing machine, which does not use an electric motor but human energy, can hardly be found for sale today unless you find it in a second-hand store or someone is selling you a vintage piece.

It is the classic type of metal machine, very heavy and usually also very stylistic. Many times they come with a small built-in cabinet.

All of them are electric, as they are powered by an electric motor. Some more advanced ones also have an electronic screen or display, while in the simplest the functions are selected by means of wheels and buttons, in an analog way.

Therefore, an electronic sewing machine is a type of electric sewing machine.

This gives rise to confusion, since sometimes we speak of “electrical machines” referring to those with electronic displays (when in fact we should be talking about electronic machines). We usually speak of mechanical machines when we refer to a modern electrical machine but with analog buttons.

Electric sewing machines are those machines that incorporate an electric motor. They are machines for professional level users.

Within this group, we can distinguish between the simplest mechanical machines, equipped with an electric motor but analog buttons; and electronic machines, which also have an electronic display system to control them.

How the sewing machine works depends on the type. The electric sewing machine works with one or more motors. These control the various functions of the machine and give it the momentum to start the sewing process. In his case, the energy provided by the motor replaces the side wheel that has to be turned manually on classic machines.

The big difference between the electric and the classic sewing machine is the motor with which it works.

The first uses electricity as a driving force, while the energy that moves the classical machine comes from human impulse (the side wheel that we have to turn to start sewing).

Today’s electric sewing machines not only have the motor as an innovative feature. They are also much lighter than the old ones, as they are made with plastic housings.

Mechanical machines only consist of an electric motor that drives the mechanism of the machine, replacing the human energy of classic machines.

The mechanism that makes the machine thing remains the same. The way to tension the thread, the position of the needle, the threading, the use of double thread or bobbin.

The way to access the different functionalities is by means of mechanical wheels and analog buttons that are manipulated manually.

In addition to the motor that makes the electronic machine work, it incorporates an electronic panel, instead of analog buttons. These regulate the various sewing functions, such as the width and length of the stitch, the type of stitch, etc.

A good example of a non-mechanical sewing machine is the Brother CS5055 Computerized Sewing Machine. This excels with its 60 built-in stitches and 7 feet, 4 bobbins, and a sewing kit.

A sewing machine is an almost inexhaustible source of possibilities. It’s for those who want to fix clothes, sew simple tears or fraying, and create their textile designs.

The mechanical machine is a simpler type of machine. It’s ideal for those who want a sewing machine for beginners and people who want to start doing simple sewing tasks.

Electronic machines are programmable and very precise machines, which is why they are preferred by people who already have a certain level in the art of sewing.

From this video, you’ll get all the basic information on how to use a sewing machine.

Below is a side-by-side comparison that’ll help you make a decision.

The similarity between the two types of machines is that you can use both to sew a seam. Although a serger cannot be used to complete a sewing job. A serger cannot make regular works such as making zippers, buttonholes, facings, or topstitching.

Both can gather fabrics, do pipings, narrow rolled gems, and hem knits.

One of the major differences between the two is that there is the bobbin that is used to perform the bottom stitch for the basic sewing machine. However, this does not exist on the serger sewing machine.

Serger sewing machines have speeds ranging from 100 up to around 9000 rotations per minute of sewing speed. A sewing machine can make around 650 to 1000 stitches per minute on average.

Sewing machines have a price ranging from as low as $80 up to around $300. Sergers start from around $200 up to around $1000

For any seamstress, the choice of owning a classic sewing machine and a serger machine is essential. Indeed, the two remain complementary and cannot replace each other. Each one has its specialties: the sewing machine remains the most suitable for straight stitching, fitting zippers, making buttonholes.

The serger machine excels at finishing, overcasting, pelletizing, flatlock seaming, and finally assembling garments. The main advantage that a serger offers remains the saving of time with a top finishing in icing on the cake.

The basic sewing machine does not cut the fabric in any way. On the other hand, the serger, for its part, cuts cleanly flush with the chain stitch all fabrics regardless of stretch or thick textiles such as jeans and imitation leathers. And thus allows a quality finish. When you are done with your work, then it is necessary to cut all the excess threads and the excess fabric. The serger cuts the fabric and the simple sewing machine does not cut the fabrics.

In summary, we can see a saving of time for a better finish with the serger. However, the best way to solve this serger vs sewing machine debate is to buy a serger and a classic sewing machine.