Can cast iron be welded or not? One common, widespread belief is that something like this is not possible. This judgment is based on an opinion that is spread among do-it-yourselfers almost in the style of a hiking legend.

Otherwise, the reason given is that the high carbon content in cast iron is responsible for this and that attempting to weld only leads to the material cracking even more. Nevertheless, you can weld cast iron if you don’t ignore certain things. So, in this article, we’ll let you know how to weld cast iron successfully.

Cast iron is an important material. Since it is used a lot, it breaks a lot and the parts that are stressed must either be repaired by welding or replaced. Cast iron is mainly used wherever there are vibrating parts or where there is high stress because the cast is impacted in a jerky manner. In vehicles, you immediately think of the chassis, the steering, the engine, and the brakes. Fastening parts made of cast iron are also used in the construction of the formwork. In the rest of the article, we’ll see how to weld the material.

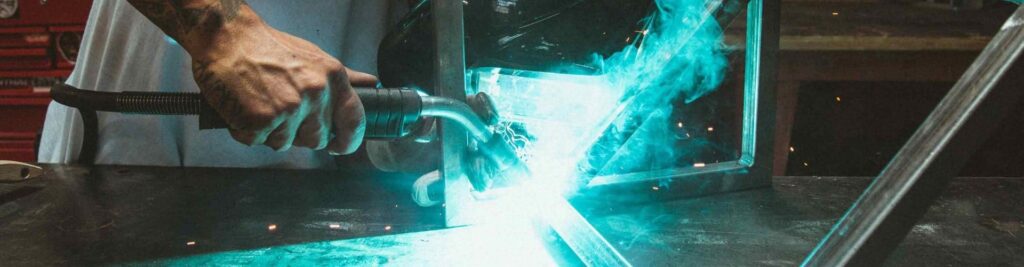

Welding cast iron, just like other metals, require the utmost care and the use of the right materials.

When welding cast iron, you will need a TIG, MIG, or stick welding machine. Further down, we will help you compare between these machines.

The electrode is a coated metal wire that looks like a stick. It is the terminal via which electric current goes between metallic and the nonmetallic parts of the electric circuit. It must be made of materials similar to the cast iron being welded. Hence, nickel alloy electrodes are the most used for cast iron welding. They are strong and have a lower coefficient of thermal expansion.

You’d need to use a welding helmet, safety goggles, welding gloves, and a welding work suit or apron. These equipment are the most important materials you must have for any welding project. It’s not for welding efficiency of course, but for personal safety. Welding without a pair of safety goggles can expose you to the “welder’s flash,” which is known as photokeratitis. The flash can cause severe burns on your eyes or face, blinding such a person permanently in seconds.

Here, we consider some important steps you need to take before you start welding.

As mentioned earlier, you should have a suitable electrode for welding cast iron on ground. Our experts recommend selecting the Blue Demon ENiFe-Cl Tube Nickel 55 cast iron. It is made of nickel and can be used for repairing castings.

The most common types of cast irons are grey and white cast irons. Nickel and nickel-iron electrodes are ideal for grey cast iron. However, white cast irons are often very hard and usually considered unweldable because of the iron carbides they contain.

First, you have to prepare the edges of the cast iron. The opening angle of the edges must be greater than for structural steel. All edges must be rounded. In principle, it is preferable to prepare the U-shaped edges. All cracks must be opened to ensure accessibility. For repair, small holes must be drilled at the ends of the cracks to stop evolution.

Since cast iron has a porous microstructure, the presence of oil and other liquids could affect its weldability: they must be removed before welding. To burn these liquids, preheating is necessary.

Whether MIG, TIG-welding with electrodes, or with the torch – there are various welding devices to choose from for do-it-yourselfers. Simple welding devices for stick electrodes are already quite inexpensive to find on the market because this method is widespread. However, the stick electrodes are a little more expensive than a roll of welding wire, as is used in the GMAW, for example.

MIG, TIG, and stick welding, also known as electrode welding, are the most common welding processes. Also, other methods are practiced, including MAG or FCAW. Each method of welding has been developed for specific applications. Accordingly, all welding methods have real advantages for some work, while they are less or not useful for other workpieces. The welding devices are correspondingly different, although a common device can be used for some types of welding.

In the GMAW, protective gases such as argon or helium are used. GMAW is also known as MIG welding.

This simple to learn welding process enables higher productivity. Very similar to the FCAW, with the GMAW, we use consumable electrodes, i.e. a wire that is wound on a roll and advanced by the welding device.

This electrode, which is supplied by direct current, is required to generate an arc to weld parts of metal together. All MIG welding procedures use a protective gas, whereby various gases come into question.

MIG is probably the most popular in GMAW processes. MIG uses inert gases such as helium and argon. This ensures the method can be used for welding metals like aluminum which are non-ferrous.

MAG, meanwhile, uses the combination of carbon dioxide, oxygen, and argon, as active protective gases. MIG is better suited for welding cast irons and steel, even if they have rusts on them.

The popularity of MIG is based on the fact that this welding process can be learned quickly and offers unbelievable versatility. MIG can also be used for semi-automatic, automatic, as well as manual processes. However, a MIG welding machine has to be serviced about twice as often as is necessary.

A non-consumable tungsten electrode is used in the TIG welding process. Therefore, in the case of the popularly used TIG welding method, an additional melting wire or a melting rod must be supplied. This welding process can be deployed extremely flexibly, both on non-ferrous as well as ferrous metals, and can also be used with and without filler.

When you compare it to other types of welding processes, TIG or GTAW is the most difficult to master. GTAW offers much lesser control over the arc and also over the so-called weld pool, the mass, and expansion of the molten material. Regardless, TIG still remains very popular. This is because the weld seams produced are of really high quality. They are very precise, and durable.

Also, the relatively small arc makes it possible to work on metals that are thin. Even the repair of molds, for which only tiny tolerances are usually allowed, can be mastered by an experienced welder with the TIG process.

SMAW, known as shielded metal arc welding and informally as stick welding, is probably the best-known welding process of all. In stick electrode welding, a consumable electrode that is coated with a powdered flux is used. The stick welders are usually the best welding machines for beginners looking for an easy to practice technique.

SMAW is a manually operated welding process. This process is quite similar to the one known as the FCAW. However, the biggest difference is that with the SMAW, all the electrode is usually coated with what is called inert gas, a flux, while with the FCAW this flux is to be found in the electrode’s core.

The main advantages of the SMAW processes are their flexibility, cost as well as simplicity. Welders only need a few equipment to start. The usual protective equipment, a welding device, and a pack of electrodes are sufficient for the work. Also, stick welding is ideal for beginners, because this process forgives mistakes without consequences.

Now that you have all the important information available, you can decide which welding machine is suitable for you as a hobbyist. Here again the advantages of the individual welding processes in the summary.

You can use this method outdoors, even in light winds up to about 10 km / h. A protective gas is usually not necessary. With a little experience, FCAW welding machines are easy to control and deliver acceptable results. This method was developed to weld steel and irons outside of the workshop.

These three similar welding methods are not intended for outdoor work, as the slightest gust of wind can blow away the protective gases. Depending on the process, you can process cast irons, aluminum, steel, or alloys. Even beginners can handle the welding equipment and create a good weld seam after a short training period. A protective gas is required for this welding technique.

This welding process, which is difficult to master, requires a do-it-yourselfer with plenty of experience in welding or natural talent. With the use of shielding gases, however, you can weld a wide variety of metal types, including cast iron, aluminum, or stainless steel. This welding technique can only be carried out in rooms.

TIG welder are made of light and high strength components. According to most reviews, the TIG-205DS HF TIG/Stick/Arc TIG Welder, designed by YESWELDER is by far one of the most reliable, light, and time-proven ones. It comes with a foot pedal, hammer and brush, a ground clamp, argon gas hose, electrode holder, and TIG torch with the consumables.

Apart from that, you can also choose the LTPDC2000D Non-Touch Pilot Arc Tig Welder & Stick Welder which is designed by LOTOS. It is an MMA/stick welder that has a plasma cutter, non-touch polit arc with dual voltage.

The electrode can be used for welding even in winds of up to 25 km / h. Also, this method is particularly undemanding, because only a welding device and corresponding electrodes are required, in addition to the usual protective clothing. A protective gas isn’t required because the flux on the electrodes takes over this task. All types of steel and iron, including some alloys, can be welded. It is also possible to machine rusty metals. The technique is simple, easy to control, and quickly delivers presentable results.

Incidentally, in this article, you can find out more about how an electric welding device works and the techniques to use while welding cast iron.

With cast iron welding, there are a couple of techniques you can use. These include preheating techniques and welding without preheating. We’ll also see how to seal cracks left behind.

It is not enough to simply start the welding machine and get to work straight away. The heat in the case of cast iron must always be taken into account.

With this technique, the metal should be heated before welding. The purpose of this heating is to prevent the cast iron part to be welded from warping.

Preheating is used during what is called arc welding. This consists of two components, the electricity used and a burning electrode.

Preheating is ideal for the preparation of the repair of cast iron because it burns impurities and graphite, which reduces the risk of cracks and porosities during welding.

By normal grinding at the bottom of the chamfer, dirt and impurities remain and this can cause problems during welding. For some welds, it is advisable to use the buttering technique Trusted Source Buttering | American Welding Society Education Online A variation of surface welding in which weld metal is deposited on one or more surfaces to provide metallurgically compatible weld metal for the subsequent completion of the weld. See also Surfacing, Buildup, Cladding, and Hardfacing. awo.aws.org .

The first step is therefore to drill the ends of the crack in the casting to be cemented. The reason for this may not be obvious at first glance, but it is obvious: This is to prevent the crack in the part to be patched from spreading further.

This crack is then exposed with the milling cutter in the shape of a V. The previously mentioned heating of the cast iron part to be treated is best prepared in such a way that the cast iron part is screwed to a steel plate to fix it.

Hammering should take place after every single step. The reason for this is because such a process takes the tension out of the material being processed.

Without preheating, this is also possible, but the room cannot get hotter than 60 ° C. Be sure to weld small parts and punch the weld with a hammer. This prevents the area next to the weld from tearing.

Most cast iron repairs are carried out by the ARC/SMAW process (MMA welding). You can weld without preheating according to the following recommendations:

Small cracks usually appear next to the welded areas because of the characteristics of cast irons, even when you follow good practices.

And this can be a big problem if the cast iron requires waterproofing. Meanwhile, you can seal leaks with special sealants for cast iron. Otherwise, if you leave it this way, the material can begin to rust after returning it to service.

When processing this material, certain aspects and rules should be taken into account to achieve perfect results.

When the work is finished, it is important to let the material cool down as slowly as possible.

A tempering furnace is suitable for this, but also hot sand or hot ash.

If necessary, a viable option is to use a welding blanket. In no case should the welding process be carried out just to carelessly leave everything afterwards – possibly even in cool winter weather.

Of course, you can weld cast iron. There are only a few things to consider. Preheating is usually recommended, especially for preheating techniques. With this technique, the metal should be heated before welding. The purpose of this heating is to prevent the cast iron part to be welded from warping.

Also, it is important not to forget what to do when there are cracks in the cast iron to be weld. In such a case, the welding direction must always run from the outside to the inside.

Particular attention should always be paid to handling the temperature and the heat generated during welding. This must always be observed when casting is to be welded.

With these, you should be able to master the processes on how to weld cast iron.