Stainless-steel sinks have many advantages. They are sturdy, lightweight, resistant to scratches, shocks and easy to maintain. In addition, many stainless-steel models exist, and they are very affordable.

The main problem encountered when installing a faucet on a stainless-steel sink is that they are often not perforated!

If this gives you the possibility of positioning the faucet “where you want”, you still have to drill the sink. Stainless steel Trusted Source About Stainless Steel Materials – The Why and The How | ISM Get a better sense of how certain alloy ingredients provide resistance to industrial chemicals. Like other steels, stainless steels are tough and durable. For these reasons they remain an essential material choice for most miniature valve designs. www.industrialspec.com is a hard and rather resistant material. And it can be tricky to break through if you don’t know how to do it.

We are going to see how to cut a hole in a stainless-steel sink and make a clean and neat hole to accommodate the faucet.

This absence of a hole makes people resort to passing the taps through the worktop and not through the sink. To integrate the faucet directly into the sink, you will therefore have to drill it.

It should be noted that the method of drilling a sink directly depends on its material. You have to carry out the work carefully, so as not to permanently damage or deface a new sink!

To successfully drill your sink, you must have the following tools:

Apart from the purely aesthetic aspect, poorly done drilling inevitably leads to leakage problems at the base of the future faucet.

Indeed, the O-ring (supplied with the faucet) will not be able to play its sealing role with the support (the sink). Because a badly cut hole does not have an exact diameter and very often the O-ring will not fit. Then it will cause water to seep along the fittings below the sink!

In the instructions below, we will make a 35 mm diameter hole with a 35 mm hole cutter. This is the most common diameter for installing a faucet. The Laiwei Bi-Metal Hole Saw is a good 35mm hole saw that is suitable for cutting through steel. However, depending on the faucet you have chosen, remember to check its installation diameter and get the right hole cutter!

Most kitchens are equipped with stainless steel sinks. This is a good thing as it is a material that is relatively easy to drill.

Before starting work, make sure your hole cutter is the right size. The hole must not be bigger than the tap!

Here are step-by-step instructions on how to do it:

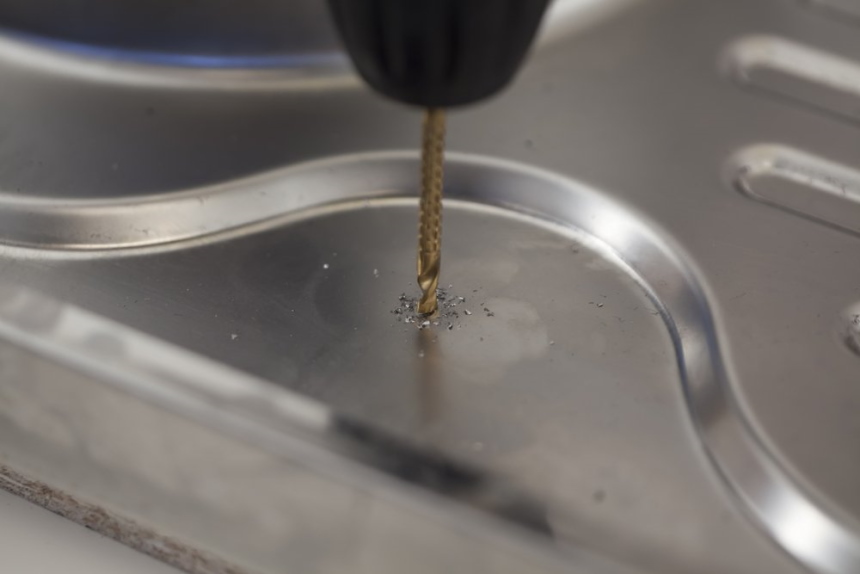

With your drill, start by drilling with a small 4 mm drill bit to make a pilot hole.

Then enlarge this hole with a larger drill of 10 mm. The DEWALT 20V Max Cordless Drill would be suitable for this job. There’s an option to include a complete drill set that includes everything needed.

Tip: When you drill metal, your drill should not turn too fast.

Before drilling a hole in a sink, note the diameter of the faucet.

A hole that is too large will inevitably lead to a problem with the faucet installation and will be neither practical nor aesthetic. If the hole is still visible at the base of the faucet, water may also flow into it and cause humidity problems.

If it is too late and the tap hole is a little too big, there are different solutions available to you:

Of course, the ideal is to drill a hole in the sink that is the right diameter!

It is better to know how to cut a hole in a stainless-steel sink when planning your kitchen or bathroom. In many cases, new sinks must be drilled when installing. Each material is indeed unique and delicate, and may therefore require special attention. However, drilling a stainless-steel sink with the right tools is child’s play. No need to call your plumber, just follow the instructions and tips provided.